A new twist on an old idea is entering the marketplace: thermal ink jet printing as an alternative to solvent-based continuous ink jet printing. This innovation uses an interchangeable print cartridge in a fashion analogous to a personal printer and puts down a fast-drying ink. Getting a fast-drying ink applied in this manner for meat-processing applications has been the lingering challenge, according to an industry source.

From the processors’ perspective the benefits can be immediate and dramatic. Maintaining continuous ink jet printers requires they be cleaned and flushed regularly, which is time-consuming and labor-intensive. The claim with a cartridge-based system is that no maintenance is required. The cartridge is just dropped in and the machine is turned on and ready for action. No warm-up. Down time is virtually eliminated. On the flip side, changeover times for continuous ink jet printers are reported to run anywhere from 30 minutes to an hour, so the savings could be significant.

It does beg the question, with such simple and fast replacement, how often do the cartridges need to be changed? I was told customers printing only “sell-by” dates have gotten up to two months use before swapping them out.

Apparently, versatility and speed are not an issue for these machines. They can be mounted on bag loaders and roll-stock machines, and print bottom webs as long as the draw is not too deep to distort the work. As for speed, they have yet to be really challenged by today’s fastest lines, one manufacturer said.

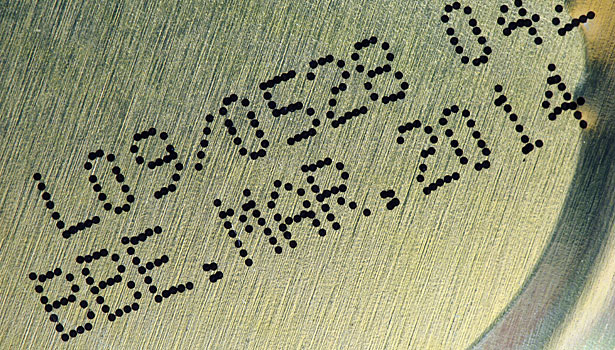

The expected programmable printing capabilities like logos, nutrition panels and graphics are standard. Color printing is a bit cumbersome, but seems to fit the demands. Black, red and blue are available. Just change the cartridge to change the color. At this time, white is not an option.

With claims of little or no maintenance, down times reduced to the bare minimum for changeover, and possibly a couple of months use from a cartridge, how much of a hit to the wallet will a packer take for a thermal ink jet printer system? I have not seen those shiny rocks, nor would I expect to; however, one estimate places the operational savings as high as 50 percent versus a continuous ink jet printer. Seems that would warrant a look which, by the way, is free.

Report Abusive Comment