Flexco announced its plans to exhibit at this year’s International Production & Processing Expo (IPPE). Flexco will be addressing the belt conveyor needs of the poultry, feed, and meat industries, offering splicing solutions for animal agriculture.

Attendees can visit booth B7464 at IPPE 2016 to see how Flexco can help operations maximize the performance of their belt conveyors. Flexco will be showcasing the breadth of its belt splicing product solutions, demonstrating how all components work in conjunction with each other for optimal system performance.

The FGP Food Grade Precleaner will be showcased at this year’s IPPE. USDA Certified for meat, poultry, and dairy, the FGP Food Grade\Precleaner meets the highest standards for food processing solutions. It is easy to install and maintain, and disassembles in a snap for regular cleaning and sanitization. The FGP Precleaner works on any belt from 4” to 60” (100 mm to 1500 mm), and the blade is available in both white and blue FDA-approved food grade material.

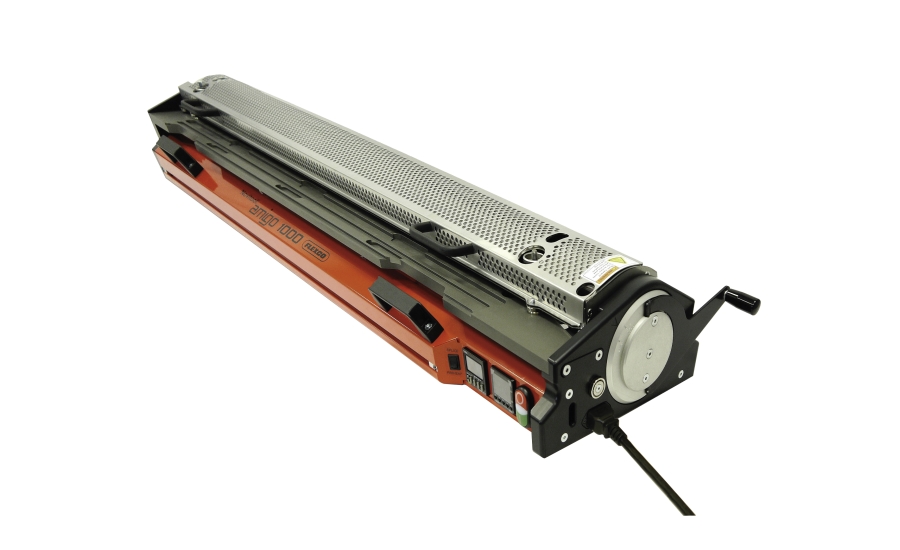

Another highlight at this show will be the Novitool Amigo, a splice press for monolithic belts. The Amigo is a new concept in the joining of solid polyester and polyurethane conveyor belts, and it produces high-quality splices in a fast and safe manner. Engineered for precision belt splicing, the Amigo features a contactless heating process that splices the belt in less than one minute. The pre-heat function removes moisture from the belt ends, avoiding unwanted pinholes in the splices, which is especially important in the food industry from a hygienic perspective.

Complete with an integrated belt cutter for safer operation, the Amigo maintains accurate pitch control in two passes. The interchangeable belt templates are designed to ensure precise pitch splicing across various monolithic belt manufacturer styles.

The Flexco team also invites attendees to check out their other products, including the air-cooled Novitool Aero Portable Splice Press, which revolutionizes endless splicing of thermoplastic belts; the Alligator Spiral Lace System, which consists of low-profile, non-metallic fasteners that are FDA-approved for food applications; the Clipper G Series Lacing System, which consists of single-stamped machine-installed lacing; and the FDA-approved Alligator Plastic Rivet System, featuring a one-piece, easy-to-clean design with rivets molded into the top plate.

Experienced Flexco team members will be available at the booth to discuss splicing systems and help attendees identify challenges and ways to increase the efficiency and productivity of poultry, feed, and meat operations. As a global leader in belt conveyor productivity, Flexco can give these operations the tools needed to take control of the belt maintenance and repair process — saving time and preserving profitability.

For more information on how Flexco can maximize your baking operation’s productivity, visit Flexco booth B7464 at IPPE 2016 or log on to www.flexco.com.

Report Abusive Comment