If there has been a gap between what is possible and what is presently being done across quality control, Anritsu Industry Solutions USA is closing it with its QuiCCA software solution.

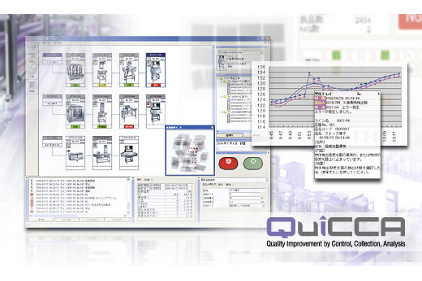

QuiCCA is the overall quality management and quality control system for all of Anritsu’s inspection equipment, spanning issues throughout all stages of production. For past logs, the software allows for auto-recording of inspection and auditing data, eliminating potentially inaccurate and cumbersome manual recording. In addition, operation histories of inspection and production statistics are automatically and chronologically recorded for centralized control. For current status, users can view production status of machines at a glance, while machine status and error messages can be sent automatically to mobile phones when connected to a mail server. QuiCCA software also helps eliminate future problems, with a centralized control that facilitates the detection of abnormalities and allows for faster, easier data analysis.

“With QuiCCA, a quality control manager doesn’t have to be concerned with constantly monitoring the status of production, because the system was developed with unmanned full automation in mind,” says Erik Brainard, President, Anritsu Industrial Solutions USA. “A processor can better monitor and diagnose a production line by finding problems quicker and easier and also improve and ensure traceability through more reliable claim handling and response quality.”

The QuiCCA quality management and control system was designed to be versatile and accessible for today’s processors. The software can be configured with multiple machines, such as automatic combination weighers, checkweighers, metal detectors and X-ray systems, or a single machine. The QuiCCA’s easy-to-read formats, including statistical displays, X-bar displays and histogram displays, deliver overall production conditions, trends and tendencies at a glance. QuiCCA’s production information can be queried by product number, lot or time period to aid investigations of past production and HACCP compliance. The information can be as simple as looking at the time/day stamped log of all rejects on a line or as detailed as reviewing each x-ray image during a time period – all the information is easily accessible in one central location.

For nearly a half century, Anritsu has been designing and manufacturing inspection equipment for the food, pharmaceutical and chemical packaging/processing industries. Formed in Japan, Anritsu has expanded its tradition of innovation and reliability to the United States over the last decade. Anritsu Industrial Solutions USA is headquartered in Elk Grove Village, IL, and can be found at http://www.detectionperfection.com.

Report Abusive Comment