Irregular or naturally shaped products pose challenges for processors due to inherent inconsistencies that affect weight control, giveaway and slicing yields. Formax’s 5 Cutting Edge Technologies are designed to handle such products to ensure accuracy while maintaining speed and slice quality.

Irregular or naturally shaped products pose challenges for processors due to inherent inconsistencies that affect weight control, giveaway and slicing yields. Formax’s 5 Cutting Edge Technologies are designed to handle such products to ensure accuracy while maintaining speed and slice quality.

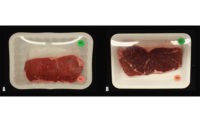

The patented Formax PowerScanner system uses cameras and lasers to generate atrue 3-D product image prior to slicing. Before it enters the slicer, the product is weighed by a scale, and a scanning unit uses lasers to define the outer shape of the product. The camera system then captures the full product shape as it passes through the lasers to create a highly accurate record of the 3-D image of the product, including all of its cracks, crevices, bumps, depressions and irregularities.

With the PowerScanner’s laser accuracy teamed with the PowerMax patented independent drive system, up to four naturally shaped products can be sliced at a time with the highest level of weight control of each sliced portion. The proactive – versus a typical reactive – scanning capability increases portion control with accept rates as high as 98% and the highest possible yields. Giveaway is reduced as well, as the use of the Formax PowerScanner leads to giveaway of less than 0.5% over target. Product consistency is enhanced, too, with exact slice count and consistent slice thickness within each draft.

The PowerScanner is part of Formax’s 5 Cutting Edge Technologies. Learn more about slicing innovations by reading a comprehensive eBook on “5 Cutting Edge Technologies to Empower Your Slicing Performance,” available at www.powermaxslicing.com.

For more information, visit www.provisur.com

Report Abusive Comment