At the direct point of contact with the product, a slicing blade can truly impacts yield and giveaway. Formax’s PowerMax blade technology is pivotal to accuracy, consistency, slice quality and efficiency.

At the direct point of contact with the product, a slicing blade can truly impacts yield and giveaway. Formax’s PowerMax blade technology is pivotal to accuracy, consistency, slice quality and efficiency.

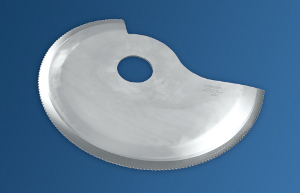

Formax blades are made from a high chromium alloy that goes through a 14-step manufacturing process designed to provide significant overall blade life. Formax's blade materials and technology allow blades to keep their edge longer with less likelihood of cracking and shattering – and, because they last longer, they are more cost efficient.

Formax’s customized blade grinding equipment produces a range of blade profiles, angles and edge serrations. Before installation, Formax technicians test an assortment of blades in different combinations to determine the optimum blade for a processor’s specific application.

Processors also have the option of having coatings applied to the surface of the blade to slice sticky or otherwise-challenging products.

By combining solid construction and innovative design, PowerMax blade technologies from Formax can lead to a 25% increase in productivity and up to a 2% increase in yields. Wear life can be boosted by more than two years, depending on the application.

Learn more about slicing innovations by reading a comprehensive eBook on “5 Cutting Edge Technologies to Empower Your Slicing Performance,” available at powermaxslicing.com.

Provisur Technologies Inc., with a family of proven brands, AM2C, Beehive, Cashin, Formax, multitec, TST and Weiler, offers a complete platform for food processing equipment, including meat recovery, separating, grinding, mixing, material handling, forming, slicing and autoloading, coating, cooking and freezing equipment for processing beef, poultry, pork, fish and other food products.

For more information, visit www.provisur.com.

Report Abusive Comment