Walk through the facilities of many mid-sized to large companies in the meat and poultry industry, and you’ll find enormous amounts of respect for history ” yet often a history that has been left behind for fresh ideas, products, strategies and leadership. That is the model of success for many” but not all have found it untenable to maintain tradition while creating highly innovative products using cutting-edge processes.

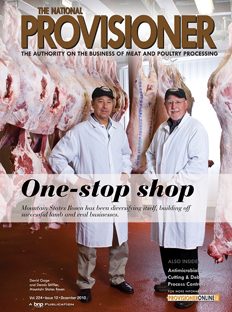

Welcome to Mountain States Rosen (MSR), the Bronx, N.Y.-headquartered processor known for its lamb and veal operations, which has been transforming itself into a customer-centric specialist offering a wide variety of proteins and products in a bevy of packaging formats.

In recent years, MSR (which has a second processing facility in Greeley, Colo.) has focused keenly on product diversification without losing sight of its traditional, successful business. Today, MSR offers not only lamb and veal cuts to longtime and new foodservice and retail customers, but also offers case-ready, value-added and precision-cut specialty items across a variety of proteins for those same industries.

Combined strength

In 2003, the Mountain States Lamb Cooperative (MSLC) acquired 50 percent of B. Rosen and Sons, creating Mountain States Rosen, a vertically integrated domestic lamb and veal processor with stakeholders up and down the supply chain. MSLC then acquired the remaining 50 percent of MSR in September 2008 and installed Dennis Stiffler as CEO of MSR.

Since then, MSR’s open in-house lines of communication and renewed focus have created a seemingly perfect blend of tradition and innovation ” a blend of time-tested and cutting-edge technologies and processes ” from farm to fork. David Gage, executive vice president of MSR, says success has come about based on the company’s measured steps toward merging together the many pieces to form one strong model.

“We took [producer-owners] to see some of our big customers so they get a feel for what they were asking us,” Gage explains. “And we learned on our end some of the things a producer goes through. … So I think it was just a combination of everybody taking their time and coming together as one.”

Once the two sides drilled down into the details of each other’s fundamental business beliefs, it became clear that MSR would be able to move forward with grand plans.

“When we first started talking with the co-op and the producers, I felt as though we were destined for success,” Gage adds. “We had a common foundation, but we didn’t know what we were doing in relationship to each other before that.”

Through the years, Gage admits, some things have been pleasant surprises and have led to added success at MSR, such as the producer-owners’ ability to understand, adapt and ultimately grow both the producer and marketing/sales sides of the business. The development of mutual trust soon allowed MSR to embark on its goal to develop a diverse mix of products that met its customers’ wide variety of needs. One of the first attempts was a staunch challenge, Gage says: the idea to sell Australian lamb alongside the American lamb, on which MSR had built its legacy.

“That was something that was very, very touchy for [the producers] to talk about, handling a foreign product,” he explains. “But we sat down and talked about diversification which has always been one of my goals and visions going back many, many years" and how it would be a benefit to the American producers in the long run.”

Although it is only a small part of MSR’s business today, Australian lamb was the first step toward product diversification, and it led to the offering of other proteins and value-added items.

“The more profit centers you have, the less you have to work on certain margins within only one species,” he says.

An open approach

David Bernstein, vice president of sales, believes MSR thrives because it is not structured in layers, like many large companies are, allowing it to be very customer-centric and flexible in its day-to-day operations.

“Even though we are a large company, we have a small-company mentality, so whatever the customer wants, we do it,” he adds, “and we’re capable of doing it based on the way the plant is set up.”

Furthermore, years of retail experience mixed among the company’s leadership has helped tremendously in the development and merchandising of new products and formats. Paul McCauley, director of operations at the New York facility, explains that, among five or six key employees at the New York facility, there is 100 years or more of retail cutting experience behind MSR’s product line.

“The benefits of having so much retail experience here are immense,” McCauley explains. “Cutting specs, shelf-life at the store level” a lot of wholesale operations don’t really know these things first-hand. All they’re getting is second-hand information for the retailer, but we have first-hand information because we’ve lived it for so many years.”

Gage says the sales team hits the marketplace with an edge too, and product development efforts becoming a team exercise.

“We do connect our sales to the production team, and I think it is equally important … for the sales team to be able to relay the messages back to production and have them implement those ideas,” he states. “Equally, they create products and presentations that they send back up to us. So if you don’t have those retail guys on the production floor, you’ll miss having that dialogue and understanding between the two parties.”

Added know-how

Retail experience isn’t the only area in which MSR has fortified itself via its leadership. Decades of lamb and veal production experience among the leadership at MSR leads to a better-quality product in the end, regardless of the species. Craig Caliciotti, production manager at the New York facility, and Mark Hirschorn, director of veal operations, are able to ensure top-notch lamb and veal products go out the door because of MSR’s vertical integration. Prior to the creation of MSR, quality was determined by the lambs and calves on the open market.

“Every load of lamb and veal we receive is actually critiqued by Mark and myself, and that information drills back to the individual growers,” Caliciotti says. “So we can go back and say, ‘OK, here was your lot, and here’s what you need to do to make it better.’ We’re always striving to get our product better than it was the day before.”

Stiffler relays that the veal business has been a big mover in recent years” something he believes is driven by the quality and innovation of the product.

“Over the last 18 months, in a protein that is shrinking for lots of various reasons, we’ve been able to grow that category double-digits, both in head count of animals processed through here as well as pounds,” he says.

McCauley adds that the integration of the company has been a big boost for the plant’s food-safety and traceability efforts" the former of which has earned the New York facility Level II SQF certification.

MSR’s model has led to success in lamb and veal " it’s “heritage” products ” but has positioned well for future forays beyond those two species. The company has embarked upon the road to business diversification, and it strives to keep growing its value-added product lines, including case-ready products, meatloaf and sausage, and its specialty cutting businesses, which include CAB-certified and a natural beef cutting capabilities, among others.

With the know-how, operational flexibility and open lines of communication in-house, MSR has positioned itself to be a very customer-centric company, and with more diversification, it can be a one-stop shop for many of its customers at the end of the day.

The co-op connection

During his visit to Etcheverry Sheep Co. (one of Mountain States Rosen’s producer-owners’ ranches) in southeastern Idaho, editor-in-chief Andy Hanacek sat down with Becky Gitthens, director of finance & operations for Mountain States Lamb Cooperative, and Henry Etcheverry, owner of Etcheverry Sheep Co. and stakeholder in MSR, to discuss their contributions to the cross-country integrated lamb-processing operations and MSR as a whole.Hanacek: Describe the integration of your job with the overall Mountain States Rosen company goals and strategies around diversification and partnerships with customers. How do you feel you fit into the picture and contribute to the overall effort of MSR?

Gitthens: We have amazing people involved in this company, from our producers on the Oregon Coast to the butchers on the floor in the Bronx. The whole organization is committed to delivering a unique, high-quality product to consumers, growing the business and adding value for our producer owners. One of my primary responsibilities is to facilitate the flow of information to and from the live side of the business to the meat side so everyone can be effective in their roles. … The efficient flow of accurate information between New York, Greeley, Colo., the producer and the customer is critical to maintaining the goal of one fully integrated company. In addition, it is critical that the organization is connected strategically: The live side has to appreciate the challenges on the meat side, and the meat side has to send the proper market signals to the live side.

Hanacek: What was the biggest challenge through the transition when the co-op became stakeholders/owners of the company?

Gitthens: When Mountain States Lamb Cooperative purchased the second 50 percent of MSR, the board and I had to shift our focus as a partner to that of being the owner of one truly integrated producer-owner endeavor. When the last closing document was signed on Sept. 17, 2008, we became entirely responsible for the success or failure of MSR. That new level of responsibility coincided exactly with the downturn in the economy and fiscal market meltdown. The lamb and veal business, as specialty and premium products, were hit hard in the 4Q of 2008. This added a tremendous amount of pressure to get the ship righted and sailing in the proper direction as soon as possible. We had to ensure control of our business processes, that our supply was in sync with demand and that we were positioned to protect market share. While hindsight is 20/20, we all agree that purchasing the remainder of the company and hiring Dr. [Dennis] Stiffler as CEO were two solid business decisions. The greatest challenge was communicating and coordinating with our board, lender, shareholders, and employees through that difficult stretch, on top of managing the day-to-day operations of MSLC. The board and I believed in our vision, but when the waters got rough, there was a certain amount of scrutiny from the stakeholders, and we had to keep everyone on board to successfully execute our plan.

Hanacek: Discuss how the time-tested, “open-range” lamb-ranching practices incorporated out west fit in with what MSR is trying to communicate to its customers ” especially juxtaposed against the innovative ideas of value-added products and case-ready packages.

Etcheverry: Today’s consumer is very much interested in where their product comes from, whether it was raised responsibly, if it is good for them and their family, and does it consistently taste great. Etcheverry lambs are raised in a pristine environment and have new virgin feed (native flowers, forbes and browse) everyday to produce premium lambs. These “time-tested” practices are the cornerstone of our “story.” The sustainable and humane production practices of all our producers, combined with our commitment to constantly improve the genetics of our animals, and, ultimately, deliver a lean, healthy product to our consumers is truly a point of differentiation.

Hanacek: What role do you believe you play in the company’s future, from a product quality and business diversification standpoint? With a vested interest in the company’s success, how can you contribute to these goals?

Etcheverry: As producers, we are rewarded for providing our company with quality lambs. Our sheep outfit, Etcheverry Sheep Co., works hard each day to provide the best quality possible. … As owners of the company, we are rewarded again as our company succeeds in the marketplace. We believe we have great staff, from our meat company’s CEO, Dennis Stiffler, to Becky Gitthens at the co-op. Their professionalism combined with the dedication, enthusiasm and commitment of our producers to “make” great lambs means that the sky is the limit for our company.

Report Abusive Comment