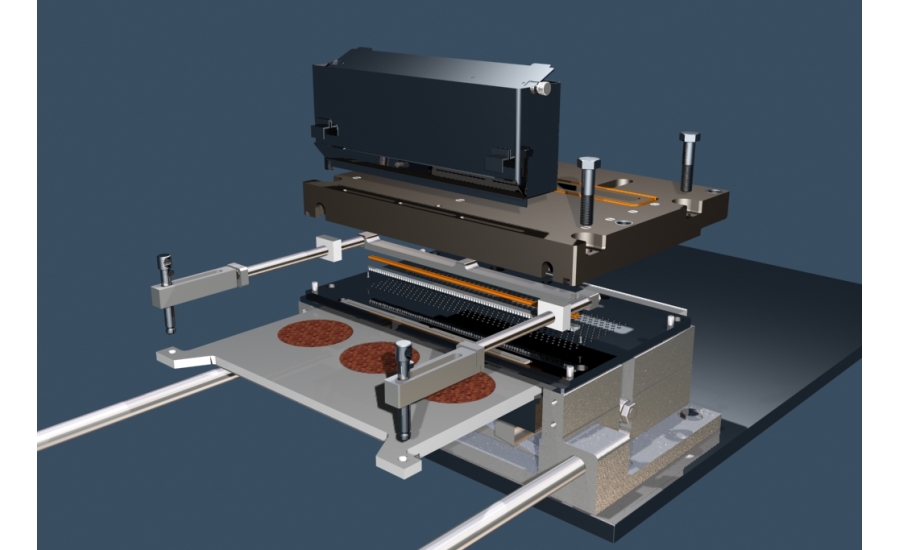

The exclusive Ultimate Patty Fill System from NuTEC Manufacturing is now available on the company’s 745 former. This system, which has been successful on NuTEC’s 710 and 720 forming machines, gives you the ability to make the best looking, best cooking patties that your customers have ever seen or tasted. Meat processors ask for it by name because of the improved bite, texture and mouth feel that the Ultimate Fill System provides. These profit-enhancing patties can be formed in portions up to 1” thick and 10 oz. in weight.

Patties that are formed with NuTEC’s unique Ultimate Fill System are assembled in random grinder sized strands instead of being subjected to the typical excessively high pressures that can result in patty toughness. The interweaving strands allow for excellent transfer of heat through the product, making cooking times faster and patties more uniform. The innovative design of the system actually creates juice pockets within the patties that enhance the juiciness. The Ultimate Fill System does all this while creating a patty with tremendous tenderness and maintaining consistent shape and weight retention after cooking. It all translates into a burger that will bring your customers back for more.

NuTEC’s Ultimate Patty Fill System also features less moving parts and components to provide superior performance with less downtime and maintenance.

For more information, contact NuTEC Manufacturing at 908 Garnet Court, New Lenox, IL 60451, call (815)722-2800 or visit www.nutecmfg.com.

Report Abusive Comment