Provisur® Technologies will highlight its latest, most comprehensive food processing solutions at the International Production and Processing Expo (IPPE) held in Atlanta January 29-31, 2013, including equipment for meat recovery, separating, grinding, mixing, forming, battering, breading, frying and slicing for beef, poultry, pork and other food products.

Provisur® Technologies will highlight its latest, most comprehensive food processing solutions at the International Production and Processing Expo (IPPE) held in Atlanta January 29-31, 2013, including equipment for meat recovery, separating, grinding, mixing, forming, battering, breading, frying and slicing for beef, poultry, pork and other food products.

All of Provisur Technologies’ brands will be represented at IPPE Booth #4608, including:

AM2C®/Beehive® Separating and Meat Recovery: SM820 Mechanical Separator from Provisur’s AM2C® line delivers high-yield mechanical separation with unparalleled performance. The rugged, stainless steel design withstands day-to-day operations, while slow rotation speed results in exceptional end-product quality.

Beehive Piranaha™ desinewing machines help remove unwanted bone, sinew and other hard parts from finished products. The Piranha is ideal for extracting sinews from beef, pork and poultry products, as well as recovering usable ground meat from a grinder’s bone collector material.

Formax® and Cashin® Slicing: CashinEDGE® HS Retail Bacon Slicing System from Provisur’s Cashin brand boosts productivity and brings a new generation of advanced performance and higher yields to the retail bacon slicing industry.

PowerMax3000® from Formax Slicing is a more powerful mid-sized slicer constructed with advanced hygiene features and up to three independent product drives for superior portion control.

New blade technologies developed by Formax Slicing across its line of slicing equipment optimize line performance and improve slice integrity, leading to higher profits by the pound.

Formax® Forming and Tooling: VerTex1000™ from the Formax Forming line from Provisur is a revolutionary forming system, combining the industry’s largest capacity with an innovative design for superior versatility, texture, and the lowest true cost of ownership. The VerTex1000 was designed to improve efficiency and sustainability by substantially reducing water usage and power consumption.

NovaMax500™, a next-generation replacement for the F19™ forming system, is transforming the industry with superior texture and low ownership costs.

Formax Tooling, available in materials including PerformAlloy®, Formalyte®, and EconoTest®, is engineered for tighter running clearances to minimize leakage and maximize usable life.

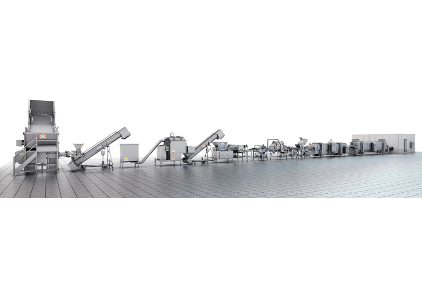

TST™Battering/Breading/Frying: TST offers complete modular solutions for battering, breading, frying, cooking, cooling and freezing. Come see our line-up:

TST™ Fryer Tunnel can be tailored to a processor’s specific needs and helps lower energy consumption, optimize product quality and maximize ROI.

TST™ Super Breader, designed for both standard crumbs and Japanese style crumbs, features a vibrating plate and pressure roll to ensure that products are perfectly breaded. The innovative hopper and feeding system help minimize the amount of circulating crumbs and is easy to clean and operate.

TST™ Combi-Dipper, engineered for high performance and ultimate sanitation with no separate parts for cleaning, allows for full batter coverage to assure that both sides of a product are coated to perfection.

TST™ Super Pre-Duster ensures product integrity, even flour distribution and the highest standards of hygiene.

Weiler® Grinding/Mixing: VersaGrind® 11 Pump Grinding System brings superior performance to processors of sausage and other meat and poultry products.

Weiler Dominator® 11 Grinder is a durable 11-inch meat and poultry grinder with Balanced Flow™ for higher throughput and improved product texture and quality.

For more information about Provisur® Technologies, Provisur’s exhibits at IPPE in Atlanta and its extensive line of processing solutions and unmatched service, visit www.provisur.com or contact Provisur at info@provisur.com or 708-479-3500.

Report Abusive Comment