Customers in the packaging, food, medical and assembly industries’ know it’s smart to have their equipment be flexible. Dorner has developed a conveyor platform that provides maximum flexibility for today and tomorrow.

Customers in the packaging, food, medical and assembly industries’ know it’s smart to have their equipment be flexible. Dorner has developed a conveyor platform that provides maximum flexibility for today and tomorrow.

Dorner’s newest flexible chain conveyor platform, the 2200 SmartFlex, is now a standard product offering that can be engineered to exact customer specifications in minutes and available with the industries’ fastest shipping.

The industry standard is to offer flexible table-top chain conveyor components, but often leave it up to the customer to cut the frame to their desired length, assemble the conveyor and make all final adjustments. That’s not the case with the 2200 SmartFlex. Dorner has removed all the guesswork of specifying and ordering a flexible chain conveyor by giving customers the ability to build complete 2200 SmartFlex conveyor assemblies to their exact layout dimensions and view it in 3D within minutes.

“Ordering and receiving a flexible chain conveyor has generally been an inconvenience for users because of the added work they’ve had to do with configuring, laying out, cutting, assembling and installing it,” said John Kuhnz, director of marketing, Dorner Mfg. “With our 2200 SmartFlex, we provide engineering tools and finished assemblies. Customers can see in 3D how the 2200 SmartFlex will interface with other conveyors and equipment, and it ships to their exact specifications with no adjustments needed.”

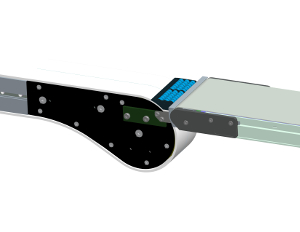

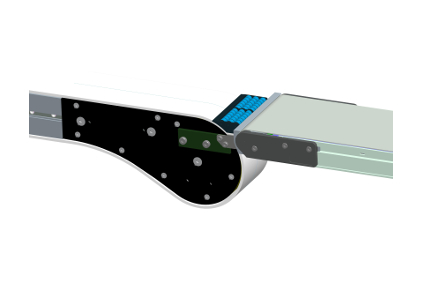

One of the many strengths of the 2200 SmartFlex is product transfers. Accessories such as infeed and exit power transfers allow for smooth end transfers for products as small as 3” diameter. The 2200 SmartFlex is engineered to seamlessly integrate with Dorner’s other 2200 Series low profile belt conveyor platforms – an advantage that gives customers the ability to select Dorner for all its mainline and support conveyor systems.

Specifications, features and benefits of the 2200 SmartFlex include:

- Ideal for the food, medical, life sciences, industrial automation and packaging industries

- Aluminum single-piece frame

- Navigates very tight corners with wheel and plain bend options

- Multiple product transfer options for end and side transfers

- Available widths of 65 mm (2.6”), 105 mm (4.1”) and 150 mm (5.9”)

- Speeds up to 250 feet per minute

- Load capacity up to 600 pounds

- Multiple chain types including low friction, friction insert, conductive, cleated, roller top and magnet top

- Made to exact customer specifications and shipped within 5 days

For more information on the 2200 SmartFlex conveyor platform, visit www.dornerconveyors.com.

Report Abusive Comment