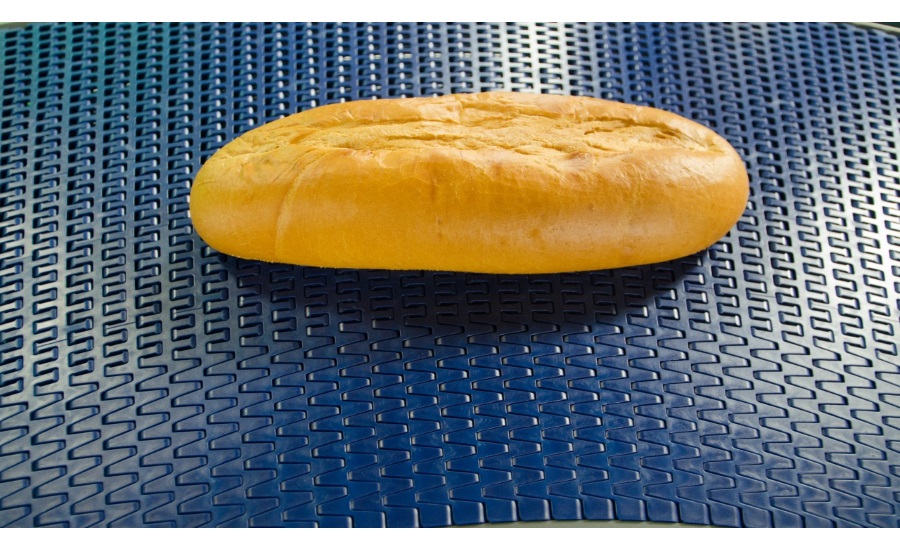

Cambridge Engineered Solutions (acquired by Rexnord in 2016) has introduced the Rexnord 1200 Series MatTop Chain, a new line of side-flexing plastic modular conveyor belts designed for moving a wide range of packaged and non-packaged food products in radius applications.

The chain can be installed on new OEM conveyor equipment or used to upgrade existing systems to carry heavier loads around corners at higher rates of speed.

The 1200 Series offers a tighter turn radius than other products on the market while reaching maximum speeds up to 246 ft/min (75 m/min) depending on the load of the chain. Smooth product handling is achieved due to the large support surface.

Food and beverage industry customers for the 1200 Series include bakeries; packaged salad, fruit and vegetables suppliers; snack food manufacturers; and refrigerated and frozen food processors.

“The 1200 Series is the first plastic chain product line to be offered to the North American market by Cambridge Engineered Solutions following Rexnord’s acquisition of the company,” said Lucas Knapp, Rexnord Global Director, Strategic Marketing. “This new product demonstrates our diversity of offerings to the food industry and our unique strength as the world’s only manufacturer of metal and plastic chain and conveyor components.”

The 1200 Series is available in four distinct versions providing solutions to all side-flexing needs.

1200 Series

1255 (1.25 flexbelt standard. Also available in SuperGrip option)

529 lb. (240 kg.) product weight/2.0x radius width/standard belt width

10.0 to 30.1 in. (255 to 765 mm.)

Capable of S turn; offset pin retention; direct food contact; SuperGrip option for packages and containers

1265 (1.25 flexbelt with reinforced outer modules)

675 lb. (306 kg.) product weight/2.0x radius width/standard belt width

10.0 to 40.2 in. (255 to 1020 mm.)

Fifty percent stronger than 1255; TwistLock pin retention; indirect food contact

1275 (1.25 flexbelt with tight fit inner radius modules)

529 lb. (240 kg.) product weight/1.2x radius width/standard belt width

10.0 to 30.1 in. (255 to 765 mm.)

Tight side-flex; offset pin retention; direct food contact

1285 (125 flexbelt with tight fit inner radius modules and reinforced outer modules

675 lb. (306 kg.) product weight/1.2x radius width/standard belt width

16.7 to 40.2 in. (425 to 1020 mm.)

Strong and tight side-flex; TwistLock pin retention; indirect food contact

Two modules are available. The outer reinforced end module makes it possible to carry heavier packages and products around curves (up to 50 percent more product weight).

The inner radius module makes it possible to construct conveyors in a more compact way, which optimizes the manufacturing footprint by saving valuable floor space between equipment.

Three edge versions are offered in the 1200 Series: Flat (Non Tab), Tab (Hold Down Tab) and Positrack (Bevel, which allows easy lift of the belt). The guiding tab underneath the belt is equipped with a separate sliding block that reduces friction and resistance in the curve without compromising the strength of the belt.

The 1200 Series chain is made from proven FDA-approved acetal and polypropylene for low friction and high strength. Cambridge Engineered Solutions also offers many metal belt options for similar food industry uses.

For more information, visit www.cambridge-es.com.

Report Abusive Comment