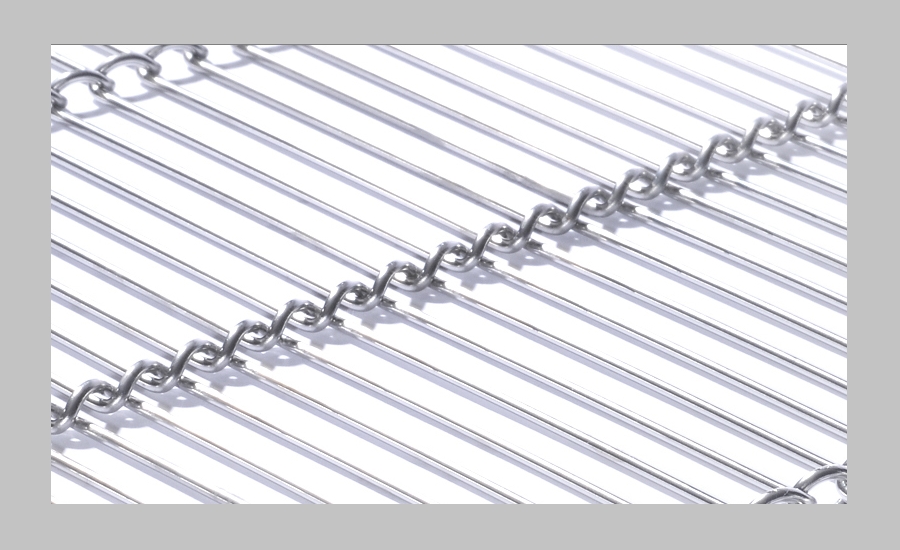

Cambridge Engineered Solutions has introduced DuraHinge Safety Edge, a new state-of-the-art, flex-style metal conveyor belt. Fabricated with reinforced edge technology to prevent snagging, DuraHinge Safety Edge improves employee safety and food handling sanitation in processing environments, particularly those in the meat and poultry industries.

The belt, a new and improved model of Cambridge’s DuraHinge® line, has a fully secured edge that allows for tight transfers in the plant. Each end loop sweeps back around to the adjacent end loop to prevent catching while maintaining enough openness for easy splicing. The belt’s outside loop dimensions match industry standards allowing it to be a universal fit for all conveyors.

“Our goal with Safety Edge is to offer a better-quality conveyor belt that removes concerns about foreign matter being transferred to food products during processing – ultimately, reaching consumers – while simultaneously creating a safer belt for employees working on the line,” said Barry Voshell, Director of Market Business Development. “This belt is far easier to clean and sanitize in a production setting than plastic belting and offers a higher ROI for plants utilizing commodity metal belts.”

DuraHinge Safety Edge will debut at the International Production & Processing Expo (IPPE) in Atlanta, Georgia Jan. 26-28. Cambridge will showcase the belt on a working conveyor at Booth B7611.

Orders made during IPPE to replace plastic belting with DuraHinge Safety Edge will receive a 10 percent discount and free shipping.

Also at IPPE, Cambridge will host “Metal Matters,” a series of programs to increase awareness of safety and sanitation issues in food processing resulting from new FSIS/USDA antimicrobial guidelines. Representatives from the USDA, insurance companies and OEMs will demonstrate and discuss metal belt advantages in food and worker safety, total cost of ownership and risk prevention.

For information visit http://www.cambridge-es.com.

Report Abusive Comment