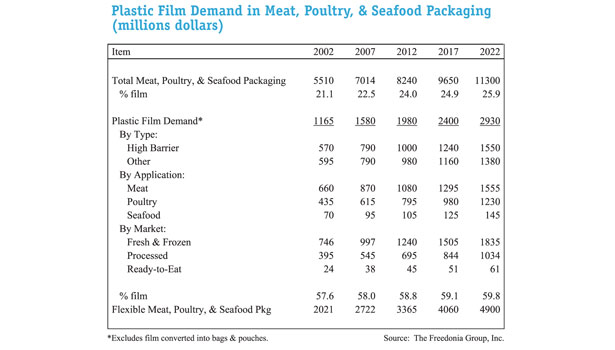

Demand for flexible packaging currently exceeds demand for rigid packaging for meat, poultry and seafood products. As a result, the market for plastic film for these products is projected to grow 3.9 percent per year to reach $2.4 billion in 2017, according to a report published in May 2013 by Freedonia, Cleveland, Ohio.(1) This means film will account for about 25 percent of the packaging used for fresh and frozen, processed and ready-to-eat products.

Sustainability-related advantages, such as lighter weight and lower shipping costs, are spurring interest in film and other flexible packaging formats like pre-made bags and pouches. On the film side, the Freedonia report predicts stronger growth for high-barrier versus commodity materials, due to the prevalence of freshness-extending vacuum packaging and modified-atmosphere packaging, as well as a growing market share for case-ready meat and rising demand for convenient ready-to-eat products.

Whether high-barrier or not, much of the film used for meat, poultry and seafood packaging runs on form-fill-seal (FFS) packaging equipment. FFS machines rely on rollstock and can produce packages with functional features such as flat bottoms, gussets, zipper reclosures, easy-open devices, perforations, special shapes and holes for hanging.

According to The Packaging Machinery Handbook by John Henry, CPP, FFS machines are characterized by how the film and product travels or by the number of seals. Vertical FFS moves film and product vertically. It’s suitable for packaging discrete pieces like IQF shrimp or assortments such as chicken pieces.

On horizontal FFS machines, product and film flows in a horizontal direction. Thus, these machines often are referred to as flow-wrappers. Since the film is formed around the item(s), this machine works well for products such as a single-serving burrito.

On three-side-seal machines, the film travels horizontally and the product travels vertically. After the film is folded in half, the sides are sealed, the product is dispensed, and the top is sealed. Although it works well with products like chicken pieces, this type of package is frequently selected for seasoning packets in dinner kit products.

Double-film FFS machines, which also are known as strip-packers or four-side-seal pouchers, rely on two film webs or a single web slit in half. Forming, filling and sealing often occur in multiple lanes. According to Henry, “Double-film machines are available in either vertical or horizontal formats. … In horizontal machines, the film is laid flat and the product placed on the lower film. The upper film is guided over the lower and sealed around the product. Vertical machines are similar except that usually the pouch is fully formed and sealed on three sides when the product is dropped (if solid) or dispensed (if liquid or powder) into the pouch through a tube. The top of the pouch is then sealed, along with the bottom of the next pouch and cut off.”(2)

Common applications include dry- or liquid-ingredient sachets in meal kits and stick packs.

Another FFS variation for meat, poultry and seafood products — thermoform-fill-seal — also relies on two webs and often runs in a multi-lane configuration. As the bottom web travels in a horizontal direction, heated tooling creates a cavity for the product. After manual or automatic loading, the top web, or lidstock, is sealed in place and packages are cut, trimmed and finished as necessary with easy-opening notches or peelable corners or header cards. Applications include case-ready meats, ready-to-eat entrees/meals and sliced lunch meat.