Home » Keywords: » form fill seal packaging

Items Tagged with 'form fill seal packaging'

ARTICLES

Packaging Tech

Form-fill-seal supports growing market

Flexible packaging materials and machines deliver longer shelf life, shelf impact and higher productivity.

Read More

Packaging Tech

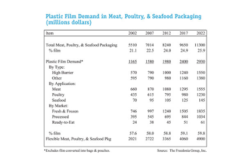

Form-fill-seal: Expanded universe

Form-fill-seal applications continue to grow, taking “near commodity” roll stock with it.

Read More

Guest Commentary

Flexible: The new package of choice

The growth of pouches and bags has form/fill/seal machinery growth outpacing the rest of the industry.

Read More

Packaging Technology

The savvy form/fill/seal shopper

Buying the right form/fill/seal system depends on attention to detail.

Read More

Get our new eMagazine delivered to your inbox every month.

Stay in the know with The National Provisioner's comprehensive coverage of the meat and poultry processing industry.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing