Illnesses Drop, Interventions Rise

by Lynn Petrak

Special Projects Editor

Special Projects Editor

As the war on pathogens grows more intense, the need for new measures remains.

Meat safety hasn’t moved to the back burner in the past decade and doesn’t seem ready to do so anytime soon. In addition to ongoing concerns about food-borne pathogens, this year’s isolated outbreaks of bovine spongiform encephalopathy (BSE) and avian influenza shone the nation’s spotlight once again on the safety of the nation’s meat supply.

The good news is that collaborative efforts throughout the food chain have made a difference. New data released by the Centers for Disease Control and Prevention (CDC) shows that infections from E. coli O157:H7 dropped 36 percent between 2002 and 2003, the largest decline ever. CDC reports Campylobacter illnesses have dropped 28 percent, Salmonella illnesses have decreased by 17 percent, and Yersinia illnesses dropped 49 percent since 1996. Illnesses caused by Listeria monocytogenes have also sharply declined during the past 10 years.

Various industry groups continue to lead the charge in many ways. Last month, the Washington, DC-based American Meat Institute (AMI) launched a new Web site, meatsafety.org, offering comprehensive information for consumers. The AMI Foundation (AMIF), meanwhile, continues to fund several research products, according to Patrick Boyle, president and chief executive officer. “In this month’s Journal of Food Protection there are several research reports that have a direct impact on meat and poultry safety,” he notes. “Several of these research programs have benefited from AMIF support or direct involvement.”

For its part, Centennial, CO-based National Cattlemen’s Beef Association (NCBA) is currently following up on industry suggestions to improve best practices, following last year’s E. coli O157:H7 summit.

“The end decision was to go back and develop best practices for the grinding sector, slaughter and fabrication, retail, foodservice, and pre-harvest,” reports James “Bo” Reagan, Ph.D., NCBA vice president of research and knowledge management, noting that most of the best practices have already been formalized and widely implemented.

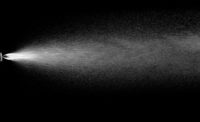

Meanwhile, interventions developed by technology suppliers also advanced. Some involve carcass handling, like advanced hide washing and sanitation. Others involve antimicrobial applications on meat surfaces, such as the use of activated lactoferrin under the Activin brand from Salt Lake City, UT-based aLF Ventures, LLC, used to detach harmful microorganisms and the use of cetylpydridinium chloride (CPC) under the Cecure brand from North Little Rock, AR-based Safe Food Corp.

Improved methods

Detection and rapid-testing methods have also improved. Hand-held tools used to detect microscopic organic contaminants are now used in major plants, which also embrace more rapid-testing technology that provides results well within a 24-hour window.

Interest in irradiation continues as well. Although one of the largest irradiation companies, San Diego, CA-based SureBeam Corp., closed its doors in January 2004, other providers have tried to fill the gap for the treatment of frozen ground beef, including Mulberry, FL-based Food Technology Services and Quakertown, PA-based CFC Logistics.

Still, while pathogens have been controlled, the industry likely will not grow complacent. As Ron Eustice, executive director of the Minnesota Beef Council and a frequent lecturer on irradiation and safety topics, points out: “The fact is that people are still becoming ill and dying from food-borne illness.”