Healthier animals make safer products. Processors are preventing foodborne illnesses by keeping animals healthy from farm to table.

In the poultry industry today, most pre-harvest interventions are focused on optimizing prebiotic and probiotic applications.

“Understanding gut health is one of the challenges to understanding how to use these products to control pathogens,” says Rafael Rivera, manager, Food Safety & Production Programs, U.S. Poultry & Egg Association, based in Tucker, Ga.

Some processors are feeding probiotics or direct-fed microbials (DFM) to animals to increase animal growth or feed efficiency, says Matthew Taylor, associate professor, meat science, Texas A&M University, based in College Station, Texas.

Research on these DFMs has yielded conflicting results on their effectiveness, but improved intestinal bacterial flora from the probiotics may reduce the risk of diarrhea, he says.

Products also exist for both poultry and beef that reduce pathogen shedding in feces — up to 50 percent, noted the study, Strategies to reduce the shedding of Escherichia coli (STEC) O157:H7 and non-O157:H7 using probiotics strains into animals.

Synbiotics, which are a probiotic and prebiotic, also promote gut health.

The poultry industry is also using Salmonella vaccinations as an important intervention.

“Vaccines are expensive so they are not used with beef, because they can’t show efficacy yet,” notes Keith Belk, Ph.D., professor of meat safety and quality, Montfort Chair in meat science, Colorado State University, Fort Collins, Colo.

Competitive exclusion and vaccines may reduce pathogen shedding as various studies indicate, including research from the University of Wisconsin-Madison.

Pre-harvest interventions to prevent or lessen the chance of E. coli contamination of beef carcasses are hide washes, trimming contaminated carcass parts, steam vacuuming, hot water and acid washes and steam treatments, notes the University of Wisconsin’s Reduction of Escherichia coli O157:H7 Shedding in Cattle by Addition of Chitosan Microparticles to Feed report.

These efforts can reduce E. coli shedding from 2 percent to 42 percent before processing, which is similar to the amount of contaminated carcasses.

Pre-harvest interventions also attempt to stop the transmission of pathogens to the environment from contaminated animals, such as nearby water sources.

“The heightened awareness on biosecurity to prevent the introduction of avian diseases also serves as a pre-harvest intervention since biosecurity focuses on keeping facilities in good repair, focuses on pest control and traffic control, and all factors in controlling the introduction of human pathogens at the farm,” says Rivera.

Flocks are sampled for antibiotics, pesticides and other farm chemicals and certified that they are free of these compounds before moving them to the processing plant.

Charging up

Carcass washes are an important antimicrobial intervention for the beef industry. They can include hot water/steam pasteurization washes, spraying organic acids such as lactic or acetic acids, peracetic acid sprays and hypochlorous acid sprays.

New carcass washing systems are being developed for the beef industry, as well.

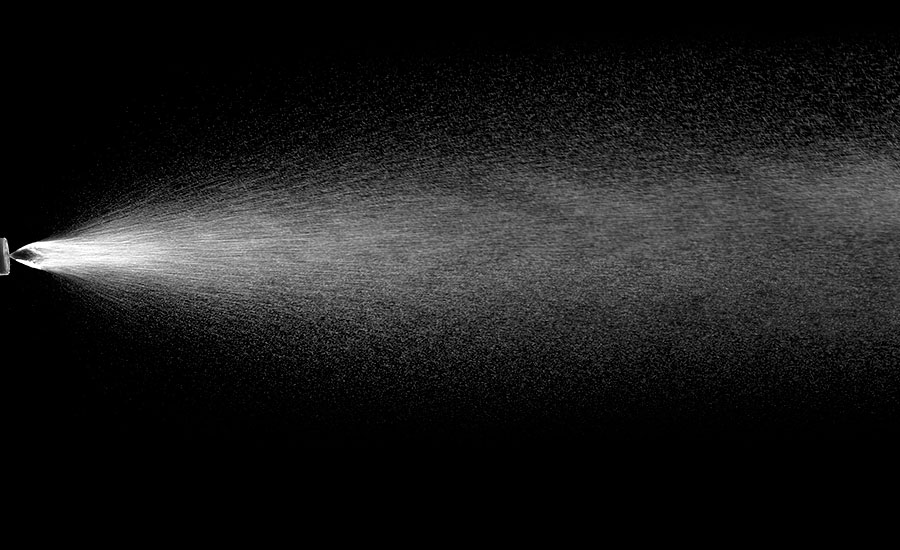

“Electrostatic spray, for one, is an effort to decrease water use and increase efficiency,” says Belk.

Electrostatic spraying of antimicrobials is a simple and quick method to cover most or all parts of the product and protect against food pathogens.

A few years ago, the Kansas State University Biosecurity Research Institute reported an electrostatic spray system (ESS) on carcasses and fabricated cuts can offer improved chemical coverage, decrease waste of food-grade antimicrobials and use less water.

Furthermore, the study said ESS technology reduces the amount of chemical antimicrobial sprays and processing water used during commercial carcass decontamination, while offering uniform coverage. The Institute was able to use an ESS system to protect an entire carcass from target pathogens like Salmonella and Shiga toxin-producing E. coli.

“New technologies like electrostatic spray have the potential to create a big impact because they change the amount of chemicals needed and decrease water use,” Belk says.

The continued development of microbial strains that have anti-pathogenic qualities, such as DFM, will only continue to evolve and improve, says Belk.

Waiting for approval

According to Belk, chemicals are available for new carcass washes but can’t be used because they aren’t approved by the Food and Drug Administration (FDA) yet — or in other countries.

“CPC (cetylpyridinium chloride) is commonly used in the poultry industry, but hasn’t been approved for beef yet,” Belk says. “The FDA has required that an application to use it be completely re-submitted, even though it’s in common products like mouthwash.”

Products that use chlorine-based washes or peracetic acid washes can’t be exported to other countries, either, he says.

“When companies develop new technologies, they need to also be approved in other countries,” Belk says.

Carcass washing procedures may be well-distributed today but their component variability — the use of cabinets, increased automation or rail speeds — can be dramatic from one packer to another, particularly between smaller packers and larger players.

“The smaller companies don’t have the financial capital to invest in increased speeds and other costly methods,” Taylor says.

The washes themselves tend to be company specific combinations, as processors can use lactic acid, another organic acid and/or hot water, he says.

“A lactic acid intervention may be applied before and after evisceration and splitting, or just after the splitting process,” notes Taylor. “Also some companies will use a 2 percent concentration of lactic acid, while others will only use hot water, for example.”

Multiple interventions reduce pathogens more than only using one wash, noted the dissertation Preventing Pathogen Contamination of Beef: Potential Application of Lactobacillus Sakei as a Biointervention and Using Indicator Bacteria Testing to Verify Intervention Treatment Efficacy, by John Raymond Ruby, at the University of Wisconsin-Madison. NP

Report Abusive Comment