Lynn Knipe

Lynn Knipe is the Extension Processed Meats Specialist and Associate Professor in Food Science and Technology, and Animal Sciences at Ohio State University. He is also a member of The National Provisioner Editorial Board. For more information, contact him at knipe.1@osu.edu or (614) 292-4877.

ARTICLES

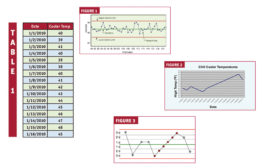

Process control: Crunch, analyze and control

Refining process-control strategies and methods for the meat industry.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing