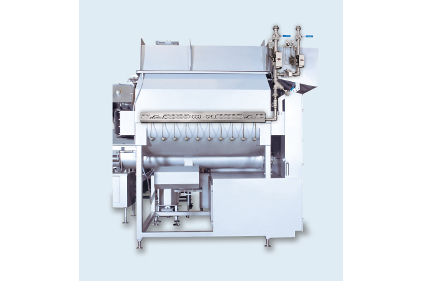

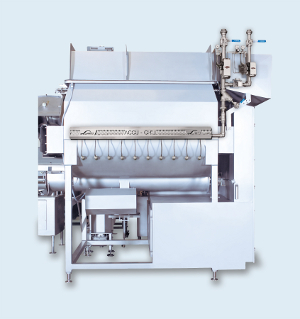

Ideal for ground meat, poultry or seafood, the patented ACCU-CHILL Bottom-Injection Chilling System from LindeLLC chills proteins from the bottom of mixers/blenders with cryogenic efficiency – and precision. Temperature can be controlled within ±1.0º F, helping to ensure consistent product quality and repeatable mixing and forming operations.

Ideal for ground meat, poultry or seafood, the patented ACCU-CHILL Bottom-Injection Chilling System from LindeLLC chills proteins from the bottom of mixers/blenders with cryogenic efficiency – and precision. Temperature can be controlled within ±1.0º F, helping to ensure consistent product quality and repeatable mixing and forming operations.

Advanced ACCU-CHILL bottom-injection (BI) chilling systems, which can use either liquid carbon dioxide (CO2) or now liquid nitrogen (LIN), are inherently more efficient than top-injected systems that typically use CO2 snow or sometimes nitrogen. In fact, top-chilling may require three times more processing time and 20-25% more cryogen to achieve the same desired temperature.

With a top-chilled mixer, CO2 snow or LIN loses refrigeration as it travels through the air from the top of the mixer, and more BTUs are lost to the mixer exhaust before the CO2 snow or liquid nitrogen is blended into the meat.

In contrast, injecting CO2 or nitrogen from the bottom of the mixer/blender as a liquid utilizes most of the refrigeration available so it is immediately available to the chilling process. The Linde food team can retrofit the ACCU-CHILL BI system to existing mixers, or design and install a customized chilling system when upgrading to new mixing or grinding equipment.

Linde is the first to configure bottom-injection chilling systems for the U.S. meat industry using liquid nitrogen (LIN), in addition to CO2. The 2014 IPPE Show in Atlanta marked the formal introduction of the re-designed Advanced ACCU-CHILL systems to the U.S. market. Advanced ACCU-CHILL systems utilizes the refrigeration more efficiently and rapidly than conventional systems.

The Linde food team assists in the selection of the cryogen which will depend on several factors, and optimizes the BI system for the plant and process to help maximize ROI.

“Even chilling systems installed just a few years ago can potentially benefit from our new technology. Engineering is that important -- and our optimized BI systems can save meat processors on the order of $300,000 or more a year,” says Mark DiMaggio, head of Food & Beverage for Linde North America.

The bottom line is that the Advanced ACCU-CHILL BI system can reach protein equilibration temperatures faster and with shorter cycle times than conventional systems. Less mixing also translates into increased production and enhanced product quality. In addition, it means less emulsified fat so case-ready packages look better, and burgers and patties are ejected from forming equipment cleanly and “smear free.”

Interstate Meat Distributors worked with Linde first to beta test the Advanced ACCU-CHILL BI system on a 2,000 lb./batch blender, and then to add the system to 3,000 and 5,000 lb. mixers as well. Interstate Meat Distributors Inc. (Clackamas, OR) processes more than 60 million pounds of ground beef and sausage a year, packaged in case-ready trays, overwrap, fresh patties, IQF patties and chubs for distribution throughout the western U.S.

Linde application engineers documented existing chilling process parameters, and designed a new proprietary hygienic nozzle injection system for multiple ports on the blending vessel, and a new exhaust system for the lid to make it a complete, matched system. (The new injection nozzles and venting system can run either CO2 or LIN.)

Easy installation, operation and hygienic design contribute to the effectiveness and efficiency of the Advanced ACCU-CHILL BI system. Besides accuracy, repeatability and high-quality results, higher efficiency can help processors achieve higher production capacities, or achieve the same capacity with reduced labor.

The Linde Food Team performs in-plant assessments and works with food processors to develop optimal solutions. For more information, contact Linde (www.lindefood.com) at 800-755-9277.