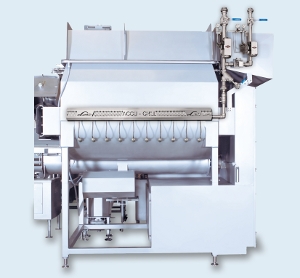

For the first time in the U.S. meat industry, Linde North America is now making its patented bottom-injection chilling systems possible with liquid nitrogen (LIN) for efficiently chilling protein product in mixers/blenders, grinders and extruders used in ground meat and poultry operations.

For the first time in the U.S. meat industry, Linde North America is now making its patented bottom-injection chilling systems possible with liquid nitrogen (LIN) for efficiently chilling protein product in mixers/blenders, grinders and extruders used in ground meat and poultry operations.

Liquid nitrogen (LIN) is a high-efficiency cryogenic gas that can offer operating cost advantages over traditional chilling systems. The Linde Food Team can retrofit existing mixers or design and install a bottom-injection system when upgrading to new mixing or grinding equipment.

Interstate Meat Distributors Inc. (Clackamas, OR), believed to be the first meat processor in the U.S. to use bottom injection with liquid nitrogen (LIN BI), reduces cycle times by 50% with a new ACCU-CHILL® BI system from Linde. Installed in 2011, the new system replaced existing components with specialized proprietary equipment. Interstate Meat packages 60 million pounds of ground beef and pork products a year for distribution throughout the western U.S.

“Even chilling systems installed just a few years ago could potentially benefit from our new technology. Engineering is that important -- and our optimized BI systems can save meat processors on the order of $300,000 or more a year,” says Mark DiMaggio, Head of Food & Beverage, Linde North America. Linde can also configure BI chilling systems to use either CO2 or LIN.

Bottom-injection systems are inherently more efficient than chilling from the top of a mixer with CO2 snow, pellets or ice. Top-chill snow horns may require 3X more time and 20-25% more cryogen to achieve the same desired temperature as BI systems.

Linde’s patented ACCU-CHILL® LIN BI provides more cold-chilling power because gas is injected from the bottom up so less gas is lost to exhaust. It also removes BTUs more efficiently and rapidly than conventional systems as liquid and gaseous nitrogen mixes through the batch. The bottom line is that LIN BI reaches equilibration temperatures faster for shorter cycle times. Less mixing also translates into increased production and enhanced product quality. In addition, it means less emulsified fat so case-ready packages look better, and burgers and patties eject from forming equipment cleanly and “smear free.”

The Linde Food Team performs in-plant assessments to identify current cost-to-chill and works with processors to develop optimal process solutions. For more information, visit: http://www.lindefood.com, or call: 800-755-9277.

For more information, read the Protein Problem Solver story on this topic by clicking here.

Report Abusive Comment