Meat and poultry processors are key catalysts in the ongoing evolution of conveyor belts.

With food safety foremost on their minds, many operators seek belts that are better able to prevent bacteria and other contaminants from taking hold. It is leading more processors to replace the traditional rubber-covered fabric conveyor belts with plastic options — primarily plastic modular belting and monolithic extruded plastic belts.

A major advantage for users of plastic modular belting is the ability to cut, dice and slice food products on the belt without puncturing the surface. Belts that can easily be cut or frayed create niches that can harbor microbials. One negative of these modular belting systems is, because sections join together like Legos, there are joints or spaces that are difficult to clean and where meat and poultry can wedge in.

Monolithic extruded plastic belts, meanwhile, do not have hinge points where food and bacteria can accumulate. The products also have smooth surfaces for easier cleaning, do not require belt tensions and do not contain fabrics that can absorb fats.

While plastic belts initially took shape in the seafood industry, where the solid surfaces better enable users to cut fish and shrimp while still on boats, they also are increasingly popular in the meat and poultry sector, says Bill Hornsby, a board member with the Milwaukee-based NIBA-The Belting Association, a belting industry trade group.

A search for safety

“The drive for more effective belts is coming from the meat and poultry processors,” says John Shelton, a NIBA board member. “Food safety, as well as interest in sanitation and cleanability, is primarily driving innovation. It is leading manufacturers of conveyor systems to partner with manufacturers of conveyor belts to come up with different product options.”

Such options include apparatus that contain antimicrobials, though the use of the agent that kills or inhibits the growth of microorganisms remains sporadic, says Vernon Smith, also a NIBA board member.

“There are some operators who are absolutely convinced that using antimicrobials is the right thing to do and will stick with it, while others are up and down with their use,” he says. “Some will use antimicrobials for six months following an E. coli breakout and then move away from it.”

Some plants, Smith notes, prefer to rely on cleaning and hygienic practices to maintain food safety.

“It looks good on a HAACP plan to be using antimicrobials, but the antimicrobials have to be in contact with a food substance for a certain period of time before it is effective,” he says. “Use is often dependent on how often the processor cleans the conveyor belt.”

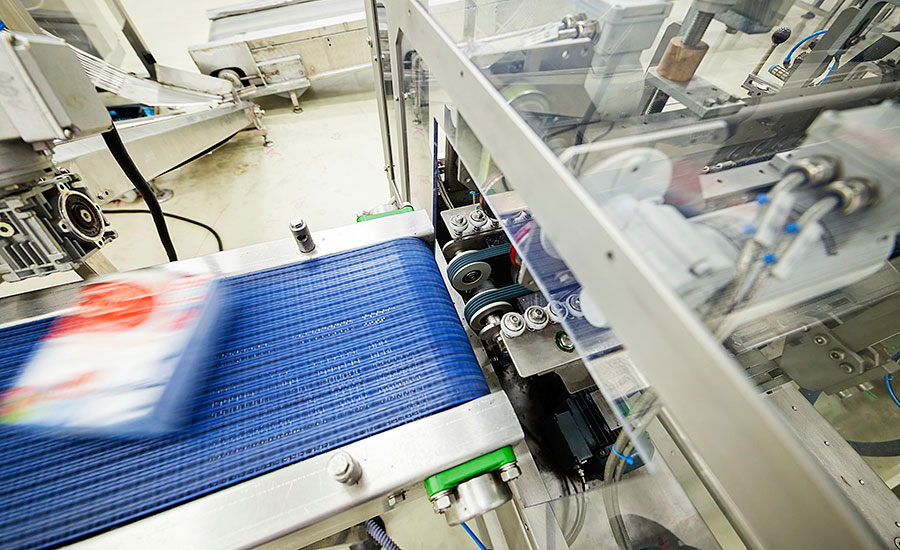

To further enhance safety, most belts are blue in color so the belting is highly visible in meat or poultry in the event that damage causes belt material to mix with food.

“When there are knives, humans and cutting involved, there is always the potential for food contamination,” Shelton says.

Time and money matters

As belts become more functional, protein processors face the increasingly challenging task of pinpointing the equipment that is optimal for their plants. In addition to considering the costs of retrofitting systems, users also must factor in operational issues, such as potential downtime from belt breaks.

While it is relatively simple for operators to repair damaged plastic modular belting, for instance, as the rod design makes it easy for users to remove and replace impaired sections, monolithic extruded plastic is more complicated.

Instead of just pulling a rod out and inserting a new section of a modular component — which could take 15 to 30 minutes — monolithic extruded plastic belting has to be melded back together after a break, a procedure that can take several times longer to accomplish, Shelton says.

Monolithic belt repairs also can be more costly because plants often have to call in outside crews to handle the task, while plastic modular belting adjustments typically can be done internally with plant workers, he says.

Moving to new types of belting, meanwhile, may require operators to modify their conveyor systems. Most belts are customized for each plant.

“Users must weigh the benefits of all the technologies versus the downsides,” Shelton says. “Processors are always looking for ways to increase their throughput, reduce costs and find more efficiency, but you can’t do that at the expense of food safety. That is what is keeping up the drive toward new innovations.”

While advanced belting technologies won’t necessarily enable plants to run conveyors at faster speeds, design elements are resulting in operational benefits. Monolithic extruded plastic belts, for instance, can last longer than older generation fabric belts, in part because of a low tension system which keeps the belts from stretching out.

In addition, many processors are cutting water expenses by 50 percent or more because newer belts require less cleaning, Shelton notes. Monolithic belts are typically quicker to wash because there are no pinch points where food can get caught. Because of such benefits, plant operators, should look at the total cost of usage versus just the price of the belt itself, he adds.

A push by protein plants

Further enhancements to conveyor belts, meanwhile, will likely be in response to the needs of the largest meat and poultry processors, Shelton says.

“The monolithic belting continues to evolve and there will be more innovation that will be driven by the end users,” he says. “Processors are looking to make sure they are getting operating efficiencies while also keeping food safety standards high.”

Among the likely upgrades will be even smoother belting surfaces, which are simpler to clean, Hornsby says.

“Surfaces are a key point in sanitation,” he says. “It’s easier for microbes to attach to a rougher surface so the technologies that are in place to create a smooth surface will be critical.”

Belting materials also will evolve, Hornsby adds.

“There are some blends that might offer better chemical resistance at a lower price or enable quicker cleaning,” he says. “Keeping up with the material technology will be important.”

Belting for conveyor systems is constantly unfolding with the increasing focus on food safety and lower operating costs triggering new designs. Protein processors, already key stimulators of newer compositions, will remain an important focus of product developers.

“The meat and poultry processors are clearly the largest consumers of the belting,” Shelton says. “It is a big, big segment and will garner a lot of attention, including more collaboration among the belt and conveyor manufacturers to meet the demands of the segment.” NP