When the Coronavirus pandemic led to panic buying of meat products, processors had to work harder than ever to maintain a steady supply of meat for American consumers. They are not the only ones working hard at this time. Texas Food Solutions, a third-party HPP (high-pressure processing) toller in Katy, Texas, has been in high demand as well.

“We’ve definitely been busy, and it’s not your run-of-the-mill busy. It’s busy while being lit on fire!” exclaims Jasmine Sutherland, president of the company. “Not only do we have more product coming in, but we also have to turn around product faster because the demand is so high.”

While the Coronavirus is not food transmissible, its use on meat products as well as other foods adds another layer of food safety at an important time. Sutherland notes that many consumers who don’t cook regularly have had to become novice chefs, as restaurants shut down.

“Inevitably, when the amateur cook maybe undercooks their product, we’re not adding food-borne illness on top of a culture already filled with a large viral load at the moment,” Sutherland says.

“I feel HPP is really hitting its stride right now. We’ve always been offering a higher level of food safety, and now the market is having to demand that, because we can’t add other things onto our problems right now,” she adds.

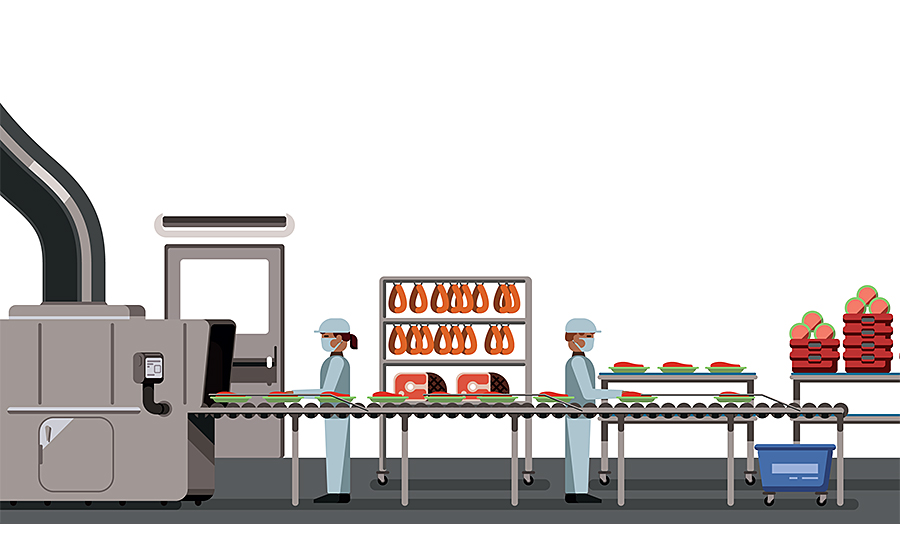

HPP is growing in usage among processors, who are either purchasing their own equipment or using the services of a toller like Texas Food Solutions. By using high pressure on some products, HPP can eliminate the dangers from food-borne pathogens like Salmonella, Listeria or E. coli.

Burgers’ Smokehouse, a California, Mo., processor, is using the process to extend the shelf life of its fully cooked country ham products.

“That’s an investment that the Burgers’ Smokehouse team made several years ago for our cooked product,” explains Kelly Perrier, director of marketing. “All of our cooked country ham under any of our three labels is part of the HPP process, for that food safety intervention.”

Sutherland says that while meat supplies are limited, waste is more of a concern than ever.

“HPP is one of the biggest tools to help us reduce waste,” she says. “One, by making a safer product, and two, by extending shelf life up to a 6X multiplier.” IP