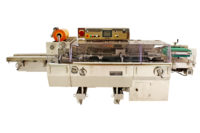

A linear press meat harvester for beef, pork and lamb bones, capable of producing different product qualities, with an unprecedented capacity of more than 10,000 pounds per hour: ProTEN, is a revolution in meat harvesting.

A linear press meat harvester for beef, pork and lamb bones, capable of producing different product qualities, with an unprecedented capacity of more than 10,000 pounds per hour: ProTEN, is a revolution in meat harvesting.

Not only does the ProTEN offer the highest capacity in the business (up to 10,500 pounds of input per hour), it’s also the most flexible and adaptable meat harvesting system. The ProTEN is capable of producing either AMR at the highest possible yield with respectable quality or the highest possible meat quality with a respectable yield.

No other meat harvesting system offers this flexibility and efficiency.

The ProTEN accepts pork, beef and lamb bones, both primal and deboned parts.

It’s flexibility and adaptability makes it possible to produce the perfect raw material for different qualities and quantities of end products, like hamburgers, fresh sausages, salami (high quality) and hot dogs, bologna sausage and luncheon meat (high capacity).

Main Benefits of the ProTEN

- Unprecedented capacity

- Meat quality on demand

- Extra yield 5-10%

- Short payback time

- Very low wear & tear

Make plans to attend Marel Days September 9 - 20 in Kansas City, KS to learn more about this remarkable new system or visit Marel.com.

Marel is a global provider of advanced equipment, systems and services to the fish, meat and poultry industries. With offices and subsidiaries in over 30 countries and a global network of more than 100 agents and distributors, the brands – Marel, Stork Poultry Processing and Townsend Further Processing – offer the convenience of a single source to meet the customers’ need.