RM2 International, the vertically-integrated innovator in pallet development, management and supply is introducing a proprietary solution to monitor pallets as they move through the supply chain. ELIoT (Electronic Link to the Internet of Things) is a track & trace monitoring device that enhances both pallet and supply chain security and provides actionable information.

“What separates ELIoT from other track & trace technologies is that it’s knitted into the fabric of the BLOCKPal™ and it’s completely maintenance free,” said David Simmons, Chief Technology Officer of RM2. “ELIoT can provide a standalone service or be seamlessly integrated into a customer’s operational IT systems.”

“ELIoT is entering the market at an opportune time as demand for technological solutions in the supply chain surges,” said David Kalan, VP of Marketing and Sales for RM2. “For example, in the US Pharmaceutical Supply Chain Act of 2012, there is a future mandate for the track and trace capability from raw materials to finished goods. This mandate is for both the product and pallet, until ELIoT there was no solution to satisfy this demand. ELIoT increases our client’s visibility and provides them with accurate location information throughout the supply chain.

“The strength, durability and reparability of the BLOCKPal translate into well over a hundred pallet trips. These characteristics combined with ELIoT, makes the RM2 BLOCKPal pallet an affordable and trackable solution comparable to both wood and plastic pallets,” said Kalan.

RM2 to participate in the AT&T LTE-M Network Pilot for the Internet of Things

RM2 International, the vertically-integrated innovator in pallet development, management and supply, will participate in AT&T’s LTE-M network pilot that promises to boost connections for the Internet of Things (IoT).

AT&T is working with a variety of technology leaders, to include RM2, to showcase the new LTE-M technology that will bring the IoT to a new generation of devices and markets. AT&T has launched North America’s first LTE-M enabled commercial site in the San Francisco market to support the pilot of AT&T’s LTE-M Low-Power Wide-Area network beginning later this month. AT&T plans to make the technology available across its commercial network throughout 2017.

RM2 International has developed RM2ELIoT, a fully integrated, zero maintenance, long-life, IoT-based track and trace solution that promises to transform the reusable packaging industry. AT&T’s LTE-M network can support the solution through enabling up to 10 years of battery life and better wireless coverage deep inside buildings and in subterranean environments.

“Our work with RM2 during our LTE-M pilot will show how this new technology can help the packaging and supply chain industries increase their efficiency and sustain the integrity of their products,” said Chris Penrose, President, Internet of Things Solutions, AT&T. “This a prime example of how innovations like LTE-M will help bring the IoT to more end points than ever before.”

John Walsh, CEO of RM2 added, “Delivering to the market a first of its kind technology solution while being a part of a group that will take this offering to the next level gives RM2 a unique product offering that separates itself from other pallet service providers while guaranteeing its solution remains at the forefront of the technological evolution of the Internet of Things.”

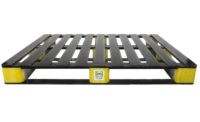

Generation 3 BLOCKPal the Integrated Pallet Powered by IoT

The Generation 3 (Gen 3) BLOCKPal has been manufactured with RM2ELIoT integrated into the pallet’s design. RM2ELIoT utilizes the Internet of Things to accurately identify its location increasing pallet and supply chain security.

“The strength, durability and repairability of the Gen 3 BLOCKPal translate into well over a hundred pallet trips. These characterises combined with the RM2ELIoT track and trace system optimizes the BLOCKPal’s ability to perform to its fullest potential.” said David Kalan, RM2 VP of marketing & business development. “RM2ELIoT connects the Gen 3 BLOCKPal to the Internet of Things, providing pallet data that has never been offered before, making the RM2 BLOCKPal the pallet solution for the new age of the Internet of Things.”

The Gen 3 channels are completely sealed, eliminating the risk of insect or bacterial contamination, making it ideal for the pharmaceutical or food industry. In addition, the Gen3 BLOCKPal has an increased coefficient of friction over traditional pallets.

Report Abusive Comment