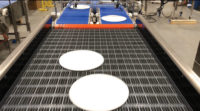

Multi-Conveyor recently built a series of powered plastic chain conveyors that incorporate manual lift gates for operator access, and pneumatic stop/clamp control for seamless merge. The overall project merges two lines fed from two (2) existing case packers down to a single lane prior to the customer’s case sealer and ultimate palletizer.

Slightly inclined, offset conveyors incorporate manual lift gate assemblies for operator access within a confined production area. The designated priority line conveys the cases to a right angle transfer maintaining product orientation. Product ultimately single files to an existing case sealer, all controlled by sensors and metering devices strategically placed by Multi-Conveyor.

Manual lift gates allow operators to easily move between production lines. We’ve used demo boxes to simulate how an operator can easily lift the infeed end of the gate assembly which triggers a pneumatic roller stop assembly to halt production. When the lift gate is lowered back into position, the pneumatic roller stop retracts to resume normal production flow.

Photo sensors and electrical safety switches were mounted and pre-wired for the mechanical lift gate assembly. Other features include LBP (low back pressure) transitions prior to the lift gates; stop clamp assemblies; and roller assist to maintain orientation through the right angle transfer.

For more information visit https://www.multi-conveyor.com.

Report Abusive Comment