Research shows consumers are looking for environmentally friendly packaging. However, they also are used to seeing a specific type of packaging for their portioned fresh meat and poultry, says Eva Almenar, a professor in the School of Packaging at Michigan State University, in East Lansing.

For many years, the industry has been shifting away from polystyrene (PS) and polyvinyl chloride (PVC) trays wrapped in film, but with portioned fresh meat and poultry being an established category, packaging changes haven’t been readily received by consumers. Instead, the fresh meat and poultry areas showing the most packaging innovation is for products aiming to reach niche consumers, such as those seeking organic and grass-fed proteins.

For many years, the industry has been shifting away from polystyrene (PS) and polyvinyl chloride (PVC) trays wrapped in film, but with portioned fresh meat and poultry being an established category, packaging changes haven’t been readily received by consumers. Instead, the fresh meat and poultry areas showing the most packaging innovation is for products aiming to reach niche consumers, such as those seeking organic and grass-fed proteins.

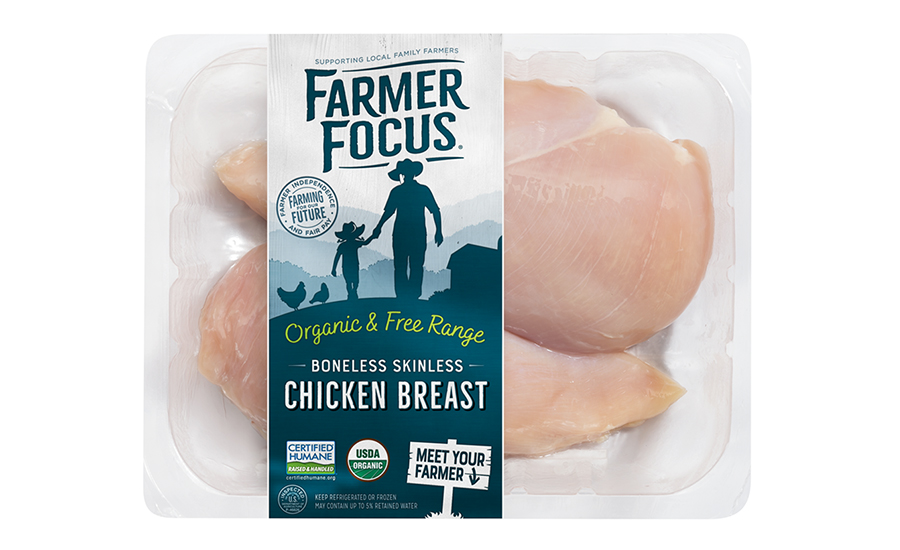

In turn, new fresh meat and poultry portioned products aren’t trending toward using trays, gases, and film anymore, but instead using vacuum packaging and vacuum skin packaging. Processors still need to use plastic packaging to protect the product and extend shelf life but are using paper wraps and paper cards as backing to communicate their product’s story and information, Almenar says. These paper options often allow processors to communicate more than the previous printable areas on the plastic. For example, Farmer Focus Organic and Free Range Boneless Skinless Thin Sliced Chicken Breast from Shenandoah Valley Organic, Harrisonburg, Va., features the chicken in vacuum packaging with a paper wrap including product, company, and farmer information around the wrap on both sides.

“This is like a new fashion for fresh meats that you can interact with the consumer a lot,” Almenar says. “You can tell a lot. You can do that with printing, and you can see the product perfectly. It looks clean, it looks fresh, it looks good and it looks appealing.”

Another example, Pre 100 percent Top Sirloin Steak — 100 percent Grass-Fed and Finished Beef from Pre Brands, Chicago, features vacuum packaging attached to cardboard backing. The product’s vacuum packaging lifts from the informational cardboard backing, allowing the consumer to see completely around the product. Additionally, the vacuum package tears from the cardboard making it easier to recycle the cardboard and the flexible vacuum package easier to store if the consumer desires. Paper wraps and backing also look more sustainable to consumers, Almenar says.

While vacuum packaging and vacuum skin packaging with paper currently is typically found on more expensive fresh meat and poultry cuts, the packaging isn’t any more expensive than a traditional tray and uses less plastic, and saves the expense of gases. Vacuum packaging also is flexible, which takes away the space needed for air and for each package during transportation. Flexible packaging also brings advantages of speed during production and sustainability with the ratio of packaging volume to food volume being less and less air being transported during shipping of packaging materials (tray vs. film) prior to packaging the product, Almenar says.

Along with the category continuing to make sustainable changes to its packaging, Almenar also expects e-commerce will have an effect on packaging. With e-commerce, consumers have bought the product before they have seen the packaging unlike the necessity of packaging for selling products in-store. “In that sense, we are saving a lot of packaging in e-commerce because the package is not going to sell the product,” Almenar says. “The product has been sold already before when the consumer is clicking.”

With the growth of e-commerce, Almenar expects to see more portion-controlled packaging that is more flexible, requires less plastic, offers extended shelf life, and isn’t easily damaged. Rigid plastic trays wrapped in film will not be necessary in e-commerce, nor will additional packaging materials needed to transport them, she says.

Report Abusive Comment