Cull cows play a significant role in fulfilling the U.S. beef demands. It is estimated that cull cows account for up to 19% of the total cattle harvested in the U.S. every year [1]. Although cull cows generate a considerable amount of beef, most products often end as ground/manufactured beef and/or low-quality cuts, substantially decreasing its economic value. This is often due to the inferior palatability, such as increased toughness and off-flavor, which is inherently generated as the animal ages.

While techniques such as brine injection and blade tenderization can be utilized as a post-harvest intervention to reduce palatability issues, consumers' demand for minimally processed meat products has been growing. Dry-aging is a natural aging method that has been known to considerably improve the palatability of meat. The process generated a unique dry-aging flavor, often reported as “beefy”, “buttery”, “nutty and “brown-roasted.” A previous study reported that dry-aging could improve the palatability of low-marbled grass-fed beef [2], showing higher flavor liking scores when compared to its wet-aged counterparts. This finding displayed great potential for dry-aging as a natural value-adding process to improve the quality of low-quality/low-value products such as cull cow beef.

During dry-aging, however, meat cuts are exposed to the environment, increasing the potential risk for microbial contamination. Multiple approaches have been developed to minimize contamination, including moisture permeable bag utilization and ultraviolet (UV) light application during the aging process. While the impact of dry-aging in moisture-permeable bags is relatively well-reported, the effect of UV-light application during dry-aging on final product quality has not been fully known yet. Therefore, the main objective of this study was to identify the impact of different aging methods on the palatability and quality of cull cow beef.

For the study, we collected paired bone-in striploin from 13 cull cow carcasses and assigned them to four different aging treatments:

- wet-aging (WA)

- conventional dry-aging (DA)

- dry-aging in moisture permeable bag (DWA)

- and UV-light dry-aging (UDA).

All the samples were aged for 28 days at 2°C, 65% relative humidity and 0.8 m/s airflow. For the UV light treatment, samples were exposed to UV light twice daily for 5 minutes per exposure. After the aging process, samples were deboned, trimmed of dried surfaces, and cut into steaks for instrumental tenderness measurement, color and oxidative stability, microbial analysis, and sensory analysis by both trained and consumer panels.

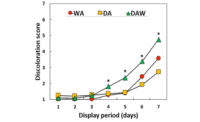

As expected from the dry-aging treatments, more product loss was observed in all dry-aged products when compared to the WA control (P<0.05), mainly attributed to the increased moisture loss and surface trimmings. However, DWA exhibited the least moisture and trim loss among the dry-aging treatments, increasing the yield by 6% compared to other dry-aging methods. In regard to meat quality and chemical attributes, similar tenderness, cook loss, lipid oxidation and protein oxidation quality were measured from all samples. The color analysis showed that DWA had the lowest color stability, demonstrated by the rapid discoloration of the products by the end simulated retail display. Interestingly, UDA steaks had comparable color and color stability to WA throughout the simulated retail display.

The application of UV light did minimize the growth of microorganisms on the meat surface during the dry-aging process. However, the inner meat portions were observed to have similar microorganism concentrations following the trimming process, regardless of the aging methods. While still unclear, microorganism presence and activity might benefit product development. Some microbial and molds have been shown to have protein and lipid degrading ability, thus potentially aiding in flavor pre-cursors liberation during aging.

For the sensory analysis, consumer panelists determined that the steaks had similar sensory attributes across all the aging treatments. The consumer panel also found that all the steaks had acceptable quality regardless of treatments. A consumer panel survey revealed a greater interest in dry-aging and dry-aged products compared to wet-aging. However, the trained panel found that DA significantly reduced the presence of sour and animal fat flavor compared to other aging methods, indicating its potential benefit for flavor improvements. The application of UV light showed a trend of increasing oxidized flavor in the final meat products in UDA samples compared to other treatments.

The findings of the current study suggested that conventional dry-aging could be utilized as a natural value-adding process to improve the palatability of cull cow beef through the reduction of off-flavor presence. Dry-aging in moisture permeable bags could increase product yield, although relatively fast discoloration should be considered for retail conditions. Implementing UV light as a safety measure might be beneficial as it minimizes the growth of surface microorganisms. However, further investigation is still needed to understand its impact on overall meat quality and palatability. More studies evaluating the effects of microorganism involvement, flavor generation process and safety of the dry-aging process should be warranted to fully utilize the beneficial impacts of dry-aging on beef quality attributes.

Acknowledgment

This study was funded by Agriculture and Food Research Initiative Grant 2017-67017-26475 from the USDA National Institute of Food and Agriculture.

References

1. USDA Livestock Slaughter Record High Red Meat and Pork Production in November; 2019;

2. Berger, J.; Kim, Y.H.B.; Legako, J.F.; Martini, S.; Lee, J.; Ebner, P.; Zuelly, S.M.S. Dry-Aging Improves Meat Quality Attributes of Grass-Fed Beef Loins. Meat Sci. 2018, 145, 285–291, doi:10.1016/j.meatsci.2018.07.004.

3. Setyabrata, D. Xue, S., Vierck, K., Legako, J., Kim, Y.H.B. 2022. Impacts of various dry-aging methods on meat quality and palatability attributes of beef loins (M. longissimus lumborum) from cull cow. Meat and Muscle Biology. 6:1-15.