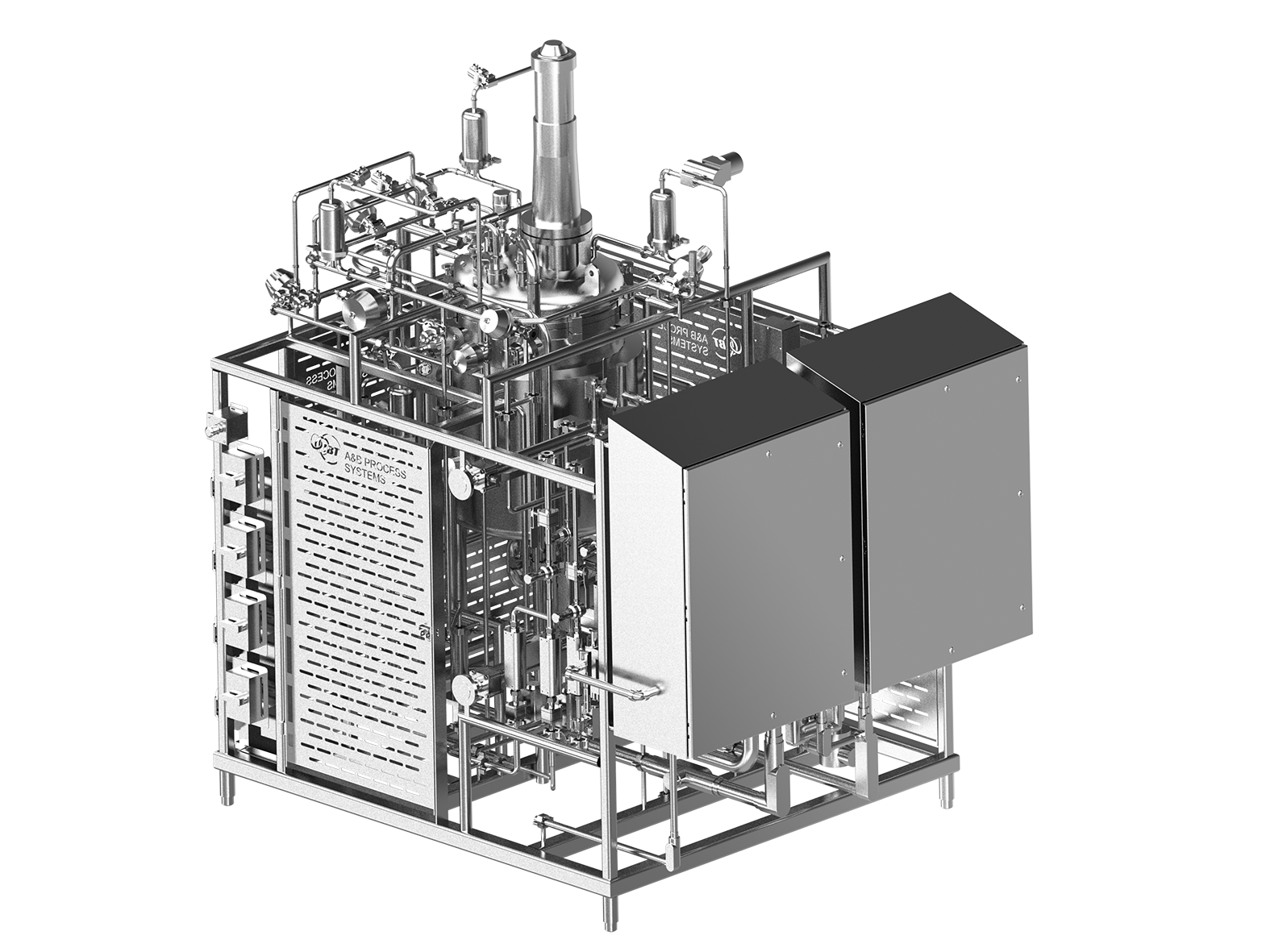

JBT Corp.’s A&B Process Systems, a leading manufacturer of custom biologic manufacturing equipment, launched the all-new READYGo bioreactor for processing companies in the cultivated meats sector. The READYGo bioreactor delivers a scalable and configurable platform that is optimized for cultivated meat products.

According to a 2021 McKinsey and Company report, the cultivated meat market could reach $25 billion by 2030. Manufactured for operational environments spanning from pilot to full-scale production, the READYGo bioreactor meets global standards for bio-processing and is ideal for scale-up work, offering customers flexibility and customization tailored to their individual, unique processes. The solution was designed to help industry processors address issues such as scalability, lead time and capital expense to meet the necessary needs of this expanding market without adding unnecessary costs to their production.

“As a vertically integrated supplier that controls its own supply chain, A&B is positioned to help the industry scale to the ever-growing demand for cell-based proteins,” said Schoen Paschka, director of sales & marketing at A&B Process Systems. “We are doing so in a way that not only integrates into the customer’s preferred component suppliers' current system, but we are able to offer our recommendations based on tenured experience if those don’t exist. This results in quality and schedules our customers can rely on in this capital-intensive sector."

No matter where in the project continuum producers stand, they can expect significant benefits from the READYGo bioreactor, including: working volume ranges from 20 liters to 20,000 liters for cell-cultured materials, and easy integration with JBT media preparation, harvest/ hold, and CIP/ SIP systems as well as protein preparation and packaging lines, allowing the quick implementation to configure the unit, and minimizing the time-to-market.

Because this production method eliminates the need to raise and farm animals for food, cell-based proteins have the potential to revolutionize the way food is produced, with major cost, environmental and food supply benefits. According to an analysis by Bloomberg, between pastures and cropland for feed, 41% of the land in the contiguous 48 states goes towards cows alone. The growth of the cultivated meat protein coincides with sustainability’s growing traction with consumers and businesses alike.

“JBT and A&B Process Systems are committed to helping our customers achieve sustainable solutions to the emerging challenges within the food supply,” said Carlos Fernandez, executive vice president of customer sustainability and market development. “As a global leader in both upstream and downstream processing solutions to the protein market, we view the success of the cultivated meat markets not only as strategic to our own success, but to meet protein demand for a growing global population successfully.”

No solution is complete without installation and overall commissioning. A&B Process Systems has over 45 years of experience in sanitary process piping in a variety of industries. With over 8 million linear feet of sanitary piping installed, A&B Process Systems has the capabilities of managing the entire installation and startup of a cell culture suite. The A&B Process Systems team consists of certified welders, automation and process engineers, and test technicians. By leveraging extensive factory acceptance testing, the team drastically reduces installation time and ultimately commission your project.

CRB, a leading provider of sustainable engineering and design solutions to the food and beverage industry, led the design of the READYGo bioreactor, drawing on the company’s deep biotech expertise to deliver a solution that empowers the cultivated meat industry to scale production and quickly, efficiently, and reliably.

To learn more about A&B Process Systems, please visit our website. You can also learn more about each of JBT's technologies and business units by visiting https://www.jbtc.com/foodtech.

Source: JBT Corp.

.jpg?height=200&t=1645742662&width=200)

Report Abusive Comment