Muller, a leading manufacturer of both innovative equipment and material load containment solutions, introduces a patented method for providing improved load containment and breathability with its Flexi-Rope system. Ideal for fresh produce, frozen foods and hot products, the new option allows users to automatically apply spaces between stretch film rotations- creating ventilation throughout the pallet. The system can be installed on new or existing Octopus ring wrapping equipment.

Muller, a leading manufacturer of both innovative equipment and material load containment solutions, introduces a patented method for providing improved load containment and breathability with its Flexi-Rope system. Ideal for fresh produce, frozen foods and hot products, the new option allows users to automatically apply spaces between stretch film rotations- creating ventilation throughout the pallet. The system can be installed on new or existing Octopus ring wrapping equipment.

“Traditional wrapping methods cover pallets completely in film, suffocating product inside,” says Michael Klear, Sales and Marketing Director, Muller. “Flexi-Rope is an easy upgrade to our standard rotary ring stretch wrap equipment that gives users necessary product ventilation.”

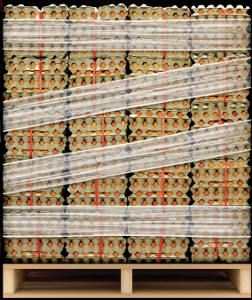

The system works by taking standard machine film rolls and roping the film from both sides to create a thinner yet strong band. As the Octopus machine automatically rotates film around the load, it leaves gaps between rotations to create air flow through the pallet and keep product fresh. Users can configure different roping combinations depending on their load. This wrap pattern flexibility ensures ideal load containment each time.

“Flexi-Rope was created from demand and is a great example of how we work with our customers to provide efficient and quality solutions to most all their load containment needs,” says Klear.

To see the application in action, watch the video at: https://www.youtube.com/embed/2mM92iJPGM4?rel=0

For general information about Muller contact directly via email: sales@mullerlcs.com, or by phone: 1-800-OCTOPUS (1-800-628-6787).

Report Abusive Comment