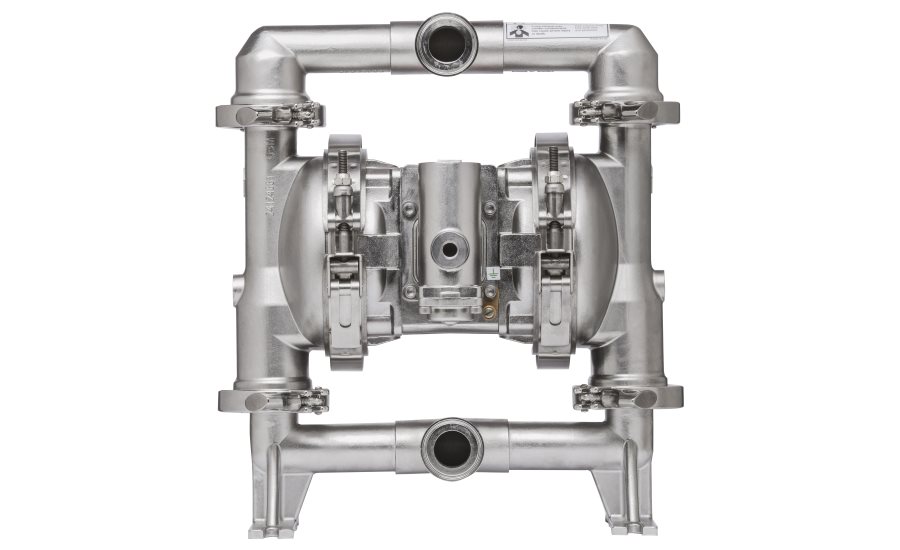

The fluid intelligence experts at ARO have expanded their SD line of pumps to include a new FDA-compliant pump with a non-metallic center body. The new pump transfers material while maintaining the integrity and purity of the material being transferred for customers in the food and beverage, cosmetic and pharmaceutical industries.

A number of advanced features make the SD pump ideal as a feed pump in a filling process, part of a “clean in place” practice or in a high-volume dispensing application. The center body of the SD pump is constructed with polypropylene and its wetted and non-wetted components are fabricated with electropolish stainless steel with 3.2um surface roughness. The ARO pumps in the SD line yields 20-30 percent better flow rates than other competitive products and ensures material is transferred unharmed. If features an optional 316L ball valve that supports the transfer of high temperature material and it features a proprietary design to ensure there is no leakage and no material waste.

The ARO SD pumps have a service life that is four times better than traditional diaphragm pumps under normal operating conditions and are known for their robust performance and low material shear. The quick-knock-down (QKD) design of the pump helps operators save time, as the pump can be disassembled rapidly for easy inspection, cleaning and maintenance.

The ARO FDA pump is available in one-inch and two-inch sizes. The one-inch pump yields a maximum available flow rate of 54 gpm (204.4 lpm) and the two-inch yields a maximum available flow rate of 192.7 gpm (729.4 lpm).

Report Abusive Comment