Home » Keywords: » pumps

Items Tagged with 'pumps'

ARTICLES

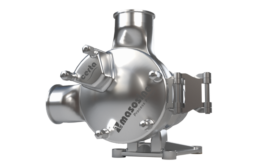

Watson-Marlow highlights its MasoSine Certa Sine pump, Qdos range of chemical meterings pumps and Bredel heavy-duty waste pumps at the upcoming IPPE.

Read More

Unibloc expands Slimline product line

This larger-capacity 14-inch Slimline pump covers higher flow rates and bigger volumes.

Read More

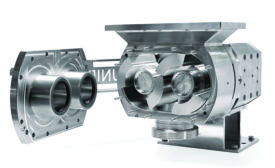

New UltraLobe FoodFirst 700 Series pump is the industry's biggest lobe pump to date

The new UltraLobe FoodFirst 700 Series pump doubles typical flow throughput.

Read More

Safe at the plate — pump design, sanitation and food safety

Proper equipment sanitation and sanitary pump design play a vital role in preventing pathogen collection and transfer.

Read More

Netzsch Pumps U.S.A. announces Tom Eisemon as the Peripro Peristaltic Pump national sales manager

Tom Eisemon has extensive experience with peristaltic pumps.

Read More

Watson-Marlow Fluid Technology Solutions highlights peristaltic and sinusoidal pumps for alternative protein market

Accurate and proven pump solutions for plant-based, cultivated meat, and fermentation applications.

Read More

Unibloc expands available sizes for QuickStrip FoodFirst 600 pump

Expanded series includes a full range of sizes from the QS FF 300 to the QS FF 677.

Read More

Unibloc expands available sizes for QuickStrip FoodFirst PD600 series pump

QuickStrip FoodFirst pump series now includes full range of sizes from the PD300 to the PD677.

Read More

Get our new eMagazine delivered to your inbox every month.

Stay in the know with The National Provisioner's comprehensive coverage of the meat and poultry processing industry.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.png?height=168&t=1665812356&width=275)