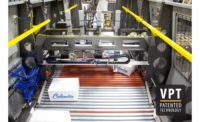

Columbia Machine recently introduced the FL6200 high-speed palletizer, a floor-level design that combines robotic-like precision with the familiar simplicity and load build quality of a conventional palletizing solution.

The FL6200 can palletize up to 120 cases per minute, depending on layer pattern – and can manage standard and challenging products including shallow unwrapped trays, shrink pads, film-only bundles and more.

One of the keys to the palletizer’s impressive performance and flexibility is the incorporation of servo technology. The NEW FL6200 combines high-speed technology with a contemporary, modular and clean design palletizer that is extremely user-friendly. As with all Columbia palletizers, the FL6200 is built with the highest priority on safety, flexibility and performance to ensure your palletizer maximizes production every day.

Columbia is renowned for the industry-leading safety and guarding system that provides “next level protection”. On the FL6200, this standard package includes Category 3, Performance Level D safety components and incorporates fully integrated guarding, full height light curtains, automatic four-point hoist pins, case infeed tunnel and interlocked load building area access doors. This safety package keeps your employees safe while still being operationally “friendly” and meeting production demands by providing convenient and safe access when needed.

Unparalleled in the industry, the FL6200 utilizes Columbia’s easy to operate Product Manager HMI, servo-actuated layer transfer and load building area hoists, servo actuated bi-parting apron plates and modular construction that allows for multiple layout configurations to fit your site constraints. Users can effortlessly create and modify layer patterns, view and export production reports, adjust component speeds and timer settings, and also access manuals and schematics, all through the HMI. Graphic pattern screens can be created at the HMI to aid recovery and provide graphic representation of diagnostics, improving OEE.

The modular construction of the FL6200 increases flexibility by allowing features to be incorporated initially or added as a modification in the future. The addition of an integrated stretch wrapper helps when load stability or space constraints are a challenge. A dual infeed can be added to meet increased line speeds. These features on the FL6200 create the ultimate palletizer that is guaranteed to meet both current and future production requirements.

There are many standard features that make this palletizer the easiest and most reliable palletizer to operate in the industry, including the simple yet robust overhead row and layer pusher components. The enhanced alarm indicators and system diagnostics, Smart Squeeze technology, and machine I/O status screens quickly communicate to the operator the status of the machine to aid in rapid machine recovery and ensure maximum uptime.

Columbia manufactures inline high speed, high-level, floor-level and robotic hybrid palletizers, load transfer stations and provides complete system integration. Columbia features flexible, upgradeable designs to speeds up to 200 cases per minute. With the broadest and most current product line available, Columbia Machine is the leading palletizing solutions provider in North America. All Columbia palletizers are built in the USA and backed by 24-hour customer support and parts service.

For more information, visit www.palletizing.com.

Report Abusive Comment