Home » Keywords: » x-ray systems

Items Tagged with 'x-ray systems'

ARTICLES

Food Safety

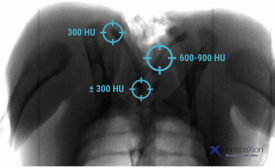

Preventing foreign-material contamination in meat and poultry processing

A 'fine' job: Foreign-material contamination can have a devastating effect on meat and poultry merchandising, but newer and more sophisticated technologies are enhancing food safety.

Read More

Get our new eMagazine delivered to your inbox every month.

Stay in the know with The National Provisioner's comprehensive coverage of the meat and poultry processing industry.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing