Home » Keywords: » equipment

Items Tagged with 'equipment'

ARTICLES

New solutions for packaging, food safety and quality assurance debut at the event.

Read More

Unibloc expands Slimline product line

This larger-capacity 14-inch Slimline pump covers higher flow rates and bigger volumes.

Read More

CMS Mechanical Solutions moves into 93,000-square-foot headquarters campus

Manufacturer also makes large capital investments in their state-of-the-art manufacturing facilities.

Read More

Duravant acquires PPM Technologies from Stonehenge Partners

Duravant expands food processing solutions portfolio with acquisition of PPM Technologies.

Read More

Your first look at IPPE 2024

The event returns to the Georgia World Congress Center in Atlanta from Jan. 30 to Feb. 1.

Read More

Handtmann launches new high-performance line for sausage producers

Line is ideally suited for the dedicated production of hot dogs in cellulose and collagen casing.

Read More

Yaskawa Motoman releases high payload palletizing robot

Ideal for logistical tasks for end-of line, distribution automation.

Read More

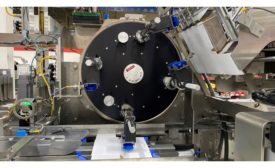

R.A Jones launches multipack speedup kit for food, beverage sectors

Canned product configurations can run at 345 cartons per minute.

Read More

M&M Carnot releases V4 Microcontroller

Microcontroller includes system controller, screw compressor controller.

October 4, 2022

ROSS CONTROLS debuts electrical isolation device

Machine offers 30-, 60-, 100-, 200-Amp rotary disconnect switch options.

October 3, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with The National Provisioner's comprehensive coverage of the meat and poultry processing industry.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.png?1647275041)