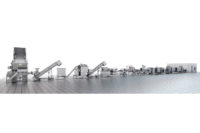

Provisur Technologies Inc., a global leader of equipment and systems for processing value-added meat, poultry and other proteins, will exhibit a range of leading integrated solutions in mixing and grinding, separating, forming, coating and cooking, plus slicing at the International Production & Processing Expo (IPPE) 2015, which takes place January 27-29 at the Georgia World Congress Center in Atlanta, Ga. Provisur will be located in Exhibition Hall B, Booth #4608.

Mixing and Grinding Solutions will includethe Weiler VersaGrind and the Weiler Omni V Multi-Grinder. The new VersaGrind Pump Grinding System increases productivity and enhances product quality for poultry and other proteins at a lower cost of ownership. Weiler’s Omni V 1107 Multi-Grinder is ideal to handle coarse grinding and rendering of frozen and refrigerated poultry, plus other proteins.

Provisur Separating Solutions will include the AM2C/Beehive Barracuda. The Barracuda gives you the freedom to choose from a range of separation heads, which results in almost unlimited configuration flexibility since you can configure the machine exactly to your specific requirements. Its modular design accommodates a wide variety of both slotted and holed filter chambers to optimize your production and the flexibility to adapt to a wide variety of applications and raw materials.

Forming Solutions will include the Formax NovaMax500, VerTex660, and the Homestyle Patty System. The NovaMax500 is the next generation of slide-plate forming technology. Its servo-controlled, rotary-product pump works in tandem feed-screw movements to prevent overworking and deliver superior product texture. A Servo Knock-Out System ensures precise product placement to downstream conveying systems. The new Formax VerTex660 rotary forming technology is designed for mid-sized processing lines and results in superior versatility, texture and the lowest cost of ownership. The Formax Homestyle Conveyor is fed by a Homestyle Patty System, which can consist of any new or existing Formax Forming machine. Superior portion control, speed and built-in paperfeed system make the Homestyle Patty System right for foodservice, case-ready, pre-cooked, fresh or frozen products.

Provisur TST Coating Solutions will include its Combination Dipper and Super Cyclone attached to the Pre-Duster. The TST Combination Dipper features a faster output belt that gently separates products for superior quality. The stainless-steel motor promises continuous power and optimal performance. Its simple, ergonomic design ensures ease of operation and cleaning. TST equipment design efficiencies include hygienic construction, low-energy consumption, sanitary design that further enhances food safety, unmatched quality, low maintenance plus low operating costs, superior operator safety, and customer value.

Provisur Slicing Solutions displayed will include the CashinEDGE Bacon Slicer with Servo Card Dispenser and the new Formax PowerMax3500 Slicing System. CashinEDGE Retail Bacon Slicing System features include a new lower product feed belt drive system, user-friendly touch-screen controls and an automated cleanup mode that can be activated with the push of a button. These advantages translate to increased throughput, higher slicing yields, improved draft presentations, and easier set-ups and maintenance with reduced giveaway.

PowerMax3500 offers the largest slicing throat in its mid-sized class with a standard 6-inch x 15-inch (152mm x 380mm) throat size or optional 7-inch x 13-inch (178mm x 330mm). These features allow you to take full advantage of up to three independent product drives to maximize productivity. If you are slicing large or heavy products, such as value-added 4-inch x 6-inch or D-shaped turkey or ham, or soft delicate products, the upper and lower infeed drives give you the support and control needed for optimum slice consistency—resulting in accurate slicing and increased yields.

Report Abusive Comment