By Mark Swanson, CEO, Birko Corp

It’s not often that competitors come together in a united effort. However, when it involves an innovation that promises to dramatically reduce waste and improve food safety, differences can be put aside.

That’s what happened several years ago when leaders in the meat processing industry joined a food safety consortium exploring the possibilities of electrostatics as applied in antimicrobial intervention. AB Foods, American Foods Group, Central Valley Meats and JBS supported food safety experts and engineers, as well as researchers from Colorado State University, in a quest to find out if electrostatic technology had the ability to revolutionize a very necessary but wasteful process.

The problem the consortium wanted to solve involved the inefficiency of common antimicrobial intervention methods. Transfer efficiency of solution to product is frustratingly low.

Dip tanks, used most often in poultry processing, may provide adequate coverage, but they waste large amounts of water and chemicals in the process. The inaccuracy of sprayers in beef processing also causes waste, and it’s a challenge to get consistent coverage. Log reductions for both methods are less than ideal but have become the norm.

On the surface, the science behind electrostatic technology is simple. Opposites attract, so negatively charged particles in an antimicrobial solution should adhere to positively charged food products. Of course, there’s no guarantee that what works in theory will provide the same real-world results. It would take years to test and perfect this new method while designing an effective piece of equipment.

Beef processors in the consortium supported the research and development of electrostatic intervention technology both financially and by providing their facilities as testing grounds. As it turns out, it was a worthy investment in the future of food safety. The results speak for themselves.

Rigorous testing shows that precision application with electrostatic antimicrobial intervention technology provides a 10x improvement on typical methods. Using approved levels of peracetic acid (PAA), in-plant pathogen log reductions are in the range of 2.0 to 2.6 or better, which easily meets or exceeds USDA requirements. That’s compared to typical log reduction of 1.0 to 1.75.

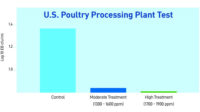

One large U.S. poultry processing facility conducted a five-day test to electrostatically apply PAA to poultry parts. During each treatment, approximately 300 pounds of poultry parts were treated. The results were very positive. The microbial load was reduced by up to 1.2 log post-treatment, chemical consumption was 70-80% less than conventional methods, and there was a reduced airborne PAA level compared to conventional methods.

For more information visit www.birkocorp.com.

Report Abusive Comment