Rockford Systems, LLC., a provider of machine safeguarding products and services, is helping manufactures achieve additional machine safeguarding protection with a complete line of pressure-sensitive safety mats and accessories.

Using weight sensors, pressure-sensitive safety mats detect the presence of workers, vehicles, or production materials and trigger an emergency stop that removes power from hazardous machinery, such as robotic welders, water jets, tube benders, conveyors, CNCs, and other machines. Only by removing pressure from the mat and switching on the control unit will power be restored to the machine. When installed correctly, the mats ensure an operator or passer-by cannot reach into the point-of-operation hazard prior to the machine coming to a complete stop, therefore preventing shearing or crushing injuries.

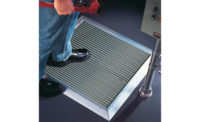

Industrial-grade Rockford Systems pressure-sensitive mats are resistant to wear, oils, grease, acids, and most common chemicals in the harshest industrial environments. Encased in the mat are conductive plates that provide stop/restart signals when pressure is applied or released. Single-piece molded construction prevents de-laminating, while tapered or straight edges allow for configuration flexibility.

All standard size safety mats can be modified with notches, cutouts, angles, or holes. Various colors, sizes, and shapes of mats can be ordered, plus different wiring options are available to meet customer requirements. To ensure fail-safe operation for critical processes and protection, Rockford Systems provides all necessary accessories for its pressure-sensitive safety mats. Along with a 20′ single-jacketed, four-wire cord exiting from the width end of the mat, there are available control modules and boxes, junction boxes, and zone monitors.

For pricing and availability, visit www.rockfordsystems.com.

Source: Rockford Systems

Report Abusive Comment