Most antimicrobial wipes, which are predominantly made of synthetic fibers like polyester and polypropylene, are discarded after a single use and end up in landfills, where they can stay for hundreds of years and become a source of environmental microplastic fiber pollution. Researchers at the U.S. Department of Agriculture's (USDA) Agricultural Research Service (ARS) recently developed sustainable, machine-washable antimicrobial wipes that can be used at least 30 times for cleaning hard and nonporous surfaces.

There has been a remarkable increase in the use of antimicrobial wipes due to the growing awareness of personal health protection. According to the Antimicrobial Wipes Market Outlook report, the worldwide antimicrobial wipes market is estimated to reach $21.6 billion by 2030.

ARS researchers developed antimicrobial wipes by using raw cotton fiber that naturally produced silver nanoparticles inside the fiber in the presence of a silver precursor. These embedded silver nanoparticles can then release silver ions that act as antibacterial agents and kill harmful bacteria.

From left to right: ARS researchers Sunghyun Nam, Matthew Hillyer and Pablo Salame use the needle punching process to produce washable antimicrobial cotton wipes in the nonwoven pilot plant at the ARS Southern Regional Research Center in New Orleans. Photo by Crista Madison.

From left to right: ARS researchers Sunghyun Nam, Matthew Hillyer and Pablo Salame use the needle punching process to produce washable antimicrobial cotton wipes in the nonwoven pilot plant at the ARS Southern Regional Research Center in New Orleans. Photo by Crista Madison.

"Silver nanoparticles are one of the popular antimicrobial agents used for producing odor-inhibiting, anti-infective textile products and other personal health products," said Sunghyun Nam, research engineer at ARS's Cotton Chemistry and Utilization Research Unit in New Orleans.

According to Nam, people will be able to clean surfaces by wetting the antimicrobial cloths with tap water and then wiping surfaces. In their research, scientists found that the wipes killed 99.9% of harmful bacteria S. aureus and P. aeruginosa on surfaces.

The technology behind this research is advantageous in several aspects. It omits the conventional pretreatments of raw cotton fibers (such as scouring and bleaching), which consume a large number of chemicals and energy. It does not require any chemical agents except for a silver precursor.

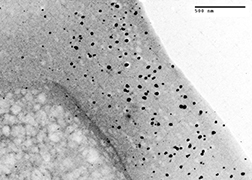

A transmission electron microscopic image of the cross-section of the treated raw cotton fiber: silver nanoparticles were produced and embedded in the primary cell wall of raw cotton fiber. Photo by Sunghyun Nam.

A transmission electron microscopic image of the cross-section of the treated raw cotton fiber: silver nanoparticles were produced and embedded in the primary cell wall of raw cotton fiber. Photo by Sunghyun Nam. It also transforms cotton fibers themselves into antimicrobial agents rather than serving as a carrier of antimicrobial agents, which is what makes them reusable. The antimicrobial wipes are made from natural cotton fibers, rather than conventional petroleum-based synthetic fibers.

To reuse the wipes, people can simply wash them in the laundry.

"We also found that the wipes still successfully killed pathogens — even after being washed 30 times in the laundry," said Nam. "The wipes regenerate their antimicrobial surface every time they are wet or washed because the embedded nanoparticles act as a reservoir of silver ions."

Nam said that another important benefit of the embedding technology is minimizing the negative environmental impacts related to the leaching of nanoparticles.

From left to right: ARS researchers Matthew Hillyer, Doug Hinchliffe, Pablo Salame and Sunghyun Nam use the hydroentanglement process to produce washable antimicrobial cotton wipes in the nonwoven pilot plant at the ARS Southern Regional Research Center in New Orleans. (Photo by Crista Madison)

From left to right: ARS researchers Matthew Hillyer, Doug Hinchliffe, Pablo Salame and Sunghyun Nam use the hydroentanglement process to produce washable antimicrobial cotton wipes in the nonwoven pilot plant at the ARS Southern Regional Research Center in New Orleans. (Photo by Crista Madison)

"These wipes are designed to gradually give off low levels of silver ions from the nanoparticles embedded inside the cotton fiber over the full course of the time of use and deplete nanoparticles," said Nam.

By developing reusable and washable antimicrobial wipes, Nam and her colleagues are aiming to find sustainable alternatives to reduce environmental waste from the disposal of single-use antimicrobial wipes.

More details about the study and the technology behind the antimicrobial wipes are published in the journal Molecules.

Source: USDA's ARS

Report Abusive Comment