So, which comes first, clean-in-place systems or plant design? All too often, it is the plant design that comes first, and then processors have to retrofit — at great cost — their equipment to be clean-in-place (CIP).

Although meat and poultry processors aren’t affected directly by the Food Safety Modernization Act’s upcoming regulations on HACCP documentation (due to already following HACCP procedures for 20 years under USDA-FSIS), it never hurts to reassess the sanitary design of their CIP or open-plant cleaning (OPC) systems.

In its most common form, CIP involves the pressure-washing of pipelines or processing equipment, or alternatively, spray-cleaning of transportation tankers and fixed tanks and processing vessels of all types in the production facility, says Dale A. Seiberling, a food industry speaker and former Ohio State University instructor in dairy technology.

“Spray-cleaning extends to include the cleaning of large spray dryers, evaporators, bins, cyclone separators and ductwork in those segments of the food-processing industry that use such equipment,” he says. This technology has been applied in a few instances to what might be considered open-plant cleaning.

“For example, in the dry cereal industry, more than 30 years ago one manufacturer wanted to reduce the labor, reduce the time and improve the efficacy of cleaning the dry cereal process,” he says. “The end result is that an area the size of a football field and 100 feet in height, with cereal production equipment arranged on space frames with open floor grating is wet washed inside and out in approximately five and a half hours, whenever required.”

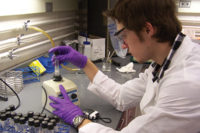

In recent years, new pumps, valves and chemicals have been created that processors use with their CIP or OPC systems to improve food safety, says Tim Bowser, Ph.D., food process engineer, Oklahoma State University, based in Stillwater, Okla.

“There have been a lot of innovations, such as surface coating and finishes that are smoother and/or have antimicrobial characteristics or anti-stick [hydrophobic] qualities, variable-speed drives [VSD] for better pump motor control, new sensors for verification of automated CIP procedures, new materials and methods of construction, better integration of controls and wireless technology, and new valves that are easier to clean and maintain,” he says.

- In particular, food safety has been improved with new technologies, he says, that include:

- Automated controls that make cleaning cycle execution almost flawless,

- Automated controls, equipment and sensors that significantly reduce cross-contamination,

- New surface finishes and technologies that make parts easier and faster to clean,

- Better chemical technology that is more effective on soils, and

- Better welding and finishing equipment that makes installations faster and cleaner.

However, the “real need is not for new technology but rather the application of ‘CIP-able’ design to all aspects of the process and the equipment involved,” notes Seiberling.

Bowser agrees that one of the biggest challenges for CIP systems is to educate processors about their importance before they design their plants.

“People don’t think of CIP when designing their plants, but it should be one of their biggest issues,” says Bowser. He notes that, for example, many plants today have issues with drainage because they tend to only contain one level.

“We need to re-think the paradigm of where to locate cleaning processes,” he says. “It’s a huge physical issue because of the way the drainage circulates as a result.”

Other remaining challenges that affect CIP are the need to “reduce the cost of installations, especially the costs of operation and cycle time, material-handling issues and improve environmental impact,” says Bowser.

At the end of the day, “the application of CIP technology is dependent on the processors’ need and/or desire to clean a processing system to the highest degree achievable by the combination of mechanical action and flow of chemical solutions,” says Seiberling.