Hurry up and get that conveyor running,” is barked over the radio as one critical piece of equipment has brought a processing department to a standstill. After locking out the equipment, the maintenance crew applies a “quick fix” and the conveyor is back up and running. The plan is to complete the repair permanently once the production slows down or when there is a long weekend.

In reality, that seldom happens.

If the repair is holding and there is no issue, then why spend time to replace the temporary fix? There are several reasons that will be discussed, but the more important reason is safety.

In addition to the quick fixes are the planned modifications to equipment or processes.

“Let’s change this design around and make some modifications,” you’ll often hear. “We have some equipment in the boneyard that can be used.”

After multiple cuts and welds, “newly” fashioned equipment is brought into the plant. Although the modified equipment may function in this new process, there are some issues that could be overlooked. Usually the boneyard is the place where one goes to make a process work when there are limited funds. At a plant I once managed, we cut and welded one certain conveyor six different times. It is not what I would recommend, but financial constraints often play into factoring repairing, replacing or modifying equipment.

These “Frankenstein” fixes and modifications often are done for the sake of expediency and costs, but in the long run there are several indicators to sound the alarm when it is time to stop repairing and modifying equipment and processes. One needs to examine the safety, functionality and financial aspects of repairs vs. replacement.

Safety

It is better to replace equipment when employee safety and food safety could be compromised. Simple maintenance can keep equipment running efficiently for a number of years. Most repairs require some type of welding, whether to fix a broken part or to add equipment. If a part is welded too many times, the structure of the metal will be compromised, which could lead to a failure point.

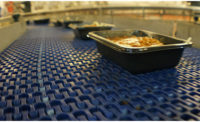

For food safety we have learned that square-tube design is not good for conveyor framework. Although there are a number of existing conveyors functioning well in plants, when those conveyors need to be replaced, they need to be replaced by units with angled framework to allow for better food safety and hygiene

If you are having equipment being tagged out of service by QA or FSIS, then you need to look at the root cause. Is it a simple fix or is there something causing contaminants to enter into the process? Metal-on-metal wear and plastic wear are indicators of major problems that need to be addressed. Continual replacement of parts and continued wearing usually indicate a need for replacement.

Functionality

Equipment processes are designed for specific purposes. When operated and maintained properly, equipment will last. But with all physical entities, there is a finite lifespan. All too often we try to overextend that time period. How does one know when there is no more utility in a piece of equipment? Several key factors can indicate when you need to replace instead of repair.

When the functionality affects productivity and incurred downtime is apparent, that is the time to start sourcing newer pieces of equipment. If a certain part continues to fail, there is more of an issue farther into the machine. For example, if one certain bearing continues to fail, it may indicate a deeper problem with a drive unit or shaft.

One other aspect of functionality is newer technology. Equipment may function well but cannot keep up with increased production speeds or a more efficient design. Newer designs will improve the plant’s overall productivity and need to be considered when investigating replacement.

Financial

Financial considerations play a role in determining when to replace equipment. When the cost of repairs (downtime, labor, yields, etc.) exceeds the purchase price of new equipment, it is time to stop repairing and begin replacing. All repairs should be tracked, whether with a preventative maintenance system (PM), maintenance management system (MMS) or other unique system a plant may utilize. By tracking the costs, one can determine when to change the equipment.

Other considerations are the payback from a new purchase. The return on investment (ROI) will be a major determinant for continuing to repair or replacing. Your choice needs to be fact-based and not simply based on what is the latest and greatest technology. Will the equipment pay for itself? What is the cost of ownership going forward?

Summary

The great feature of equipment for the food industry is how robustly it is built (for the most part). Equipment that was made in the 1950s is still running in plants today. But when the equipment has been used, fixed or modified to the point of inefficiency and cost, it needs to be replaced. With thin margins, it is not financially wise to replace something every week, but there should be a logical and patterned way of replacement.

Getting all the numbers related to safety, functionality and costs will provide you the most accurate means with which to determine repairing or replacing. Eventually equipment will need repairs or to be replaced. Tracking your asset costs and cost to produce using the equipment will guide your decision.

Report Abusive Comment