Managers and operators of plants that bread poultry or other types of food should be aware of the risks of exposure to airborne breading dust, and they should use methods known to be effective in minimizing the dust that becomes suspended in the air. Also, having periodic health checks of employees and training them to be aware of the symptoms of exposure to breading dust are important steps to preserving a healthy work environment. These measures can prevent illnesses and help reduce sick leave and employee turnover. By doing so, they allow for more efficient plant operations and reduce costs associated with employee sick leave and dust-related illnesses.

A team from the National Institute for Occupational Safety and Health (NIOSH) evaluated a poultry breading plant in Georgia at the request of the local poultry worker’s union. The union had concerns that plant employees had more cases of respiratory ailments such as asthma, bronchitis and nasal symptoms than other people.

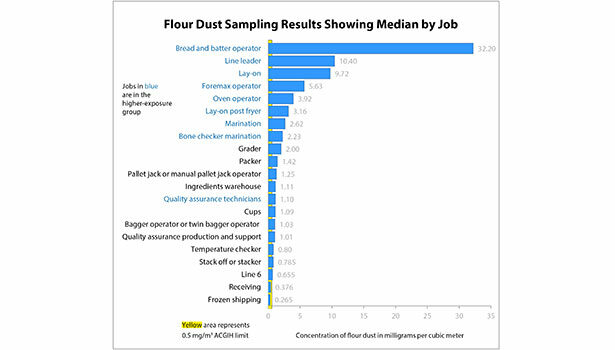

The NIOSH team looked at work processes, practices and conditions at the plant. Air samples taken at different locations and times showed the concentrations of flour dust in the air that employees breathed.

The team considered employees as “lower exposure” or “higher exposure” based on their job. Lower-exposure employees worked with product that was already cooked, on a line that did not bread chicken and in other jobs with minimal direct contact with breading dust. Higher-exposure employees handled flour and other ingredients and uncooked breaded product. Employees voluntarily gave blood samples that NIOSH tested to determine whether the employees were sensitized to flour dust, wheat, garlic, onion, soybean, corn or paprika, all of which the plant used. Sensitization is the presence of certain types of antibodies specific to a particular substance. An allergy is sensitization to a substance along with allergic symptoms when exposed to that substance.

The team asked employees about their jobs and health. Employees reported whether they had cough or symptoms of asthma or allergies. They reported whether these symptoms were better, worse or unchanged on days off work.

NIOSH found the median flour dust concentration was 8.21 milligrams per cubic meter in air samples collected from areas where higher-exposure employees worked. A median is the point at which an equal number of measurements are above and below. This was nearly eight times higher than the median air concentration from the work areas where the lower-exposure group worked.

Most samples from both lower- and higher-exposure employee groups were above 0.5 milligrams per cubic meter, the occupational exposure limit recommended by the American Conference of Governmental Industrial Hygienists (ACGIH) for flour dust. For the higher-exposure group samples, the median concentration was more than 16 times the ACGIH recommended limit. Even for the lower-exposure group samples, the median concentration was more than twice the ACGIH recommended limit. The ACGIH limit is specific to flour dust and was set to make wheat flour sensitization less likely. The company had based its occupational exposure limits on the Occupational Safety and Health Administration’s (OSHA) permissible exposure limit for particulates not otherwise regulated. OSHA’s limit is 15 milligrams per cubic meter for total dust, and 5 milligrams per cubic meter for respirable dust. The company followed OSHA’s legally enforced limit rather than the ACGIH recommended limit. NIOSH investigators recommend that employers use the ACGIH limit.

The group with the highest exposures was more likely than the lower-exposure group to report the following work-related symptoms in the past 12 months:

• Wheezing or whistling in the chest.

• Sneezing or runny nose — or a blocked nose without a cold.

• Sneezing or runny nose or blocked nose without a cold, along with itchy, watery eyes.

Employees in the higher-exposure group were more likely to be sensitized to flour dust and wheat. Employees sensitized to flour dust, wheat, corn or onion were more likely to report asthma symptoms related to work than those not sensitized.

Many employees said they often coughed at work and reported coughing regardless of whether they were sensitized to breading ingredients.

Higher dust levels led to work-related asthma symptoms, cough, and rhinoconjunctivitis (nasal congestion, runny nose, post-nasal drip, sneezing and red eyes).

Given the health conditions found at the plant and the high concentrations of breading dust in the air, NIOSH urged the employer to take these actions:

• Use an enclosed system to transfer powdered ingredients to the dispensing hoppers. Installing equipment to remove a health risk from the workplace is known as an engineering control. This solution works much better than efforts that rely on employees to take action, such as correctly wearing personal protective equipment.

• Use a local exhaust ventilation system, another type of engineering control, to lower flour dust levels.

• Train employees to recognize and report respiratory symptoms.

• Hire a physician to evaluate employees for respiratory symptoms before they begin work and regularly after that.

NIOSH urged employees to take these actions:

• Properly wear company-provided respirators. If correctly selected and worn, the respirators should lower dust levels by a factor of 1,000. The NIOSH team saw some employees wearing respirators incorrectly, which makes them less effective. Employees should use respirators until the enclosed system and local exhaust ventilation are put in place.

• Report health problems that might be related to work to their supervisor or the plant nurse. This allows the plant to refer employees for a medical evaluation.

• Use slow, smooth movements when handling powdered ingredients in order to keep airborne dust to a minimum. When pouring, employees should keep the smallest possible distance between the paper bag and the dispensing hoppers. Also when pouring ingredients, employees should keep the bag at the lowest possible height. Employees should open both ends of paper bags to reduce the dust that becomes airborne when they empty the bags.

To see the full report, go to http://www.cdc.gov/niosh/hhe/reports/pdfs/2009-0131-3171.pdf.

Employees, employee representatives or employers can request an evaluation of possible health hazards at a job or workplace. To request an evaluation, go to www.cdc.gov/niosh/hhe/request.html, call (800) CDC INFO (232-4636), or e-mail HHERequestHelp@cdc.gov.

Report Abusive Comment