As a custom processor that delivers a variety of products to a variety of customers, Deli Star Corp. has to speak a variety of languages. If a sandwich maker wants to discuss food safety, the Fayetteville, Ill. company’s food scientists review its post-pasteurization processes and shelf life guarantees. If a restaurant chain wants to discuss what’s hot, a sales team gives a presentation on food trends and how Deli Star’s products line up with those trends. Or, if a restaurant chain’s culinary experts want to talk shop, they meet with Deli Star’s own executive chef and spend a day in the test kitchen, creating potential new menu items.

More often than not, a customer meeting can involve multiple scenarios, requiring some nimbleness on the part of the processor. Such is life at Deli Star, a provider of a multitude of services, from menu ideation to meat processing education to production of numerous cooked meats and deli products. Not that the company is complaining; the team prides itself on being able to provide solutions and be a value-added partner to its customer base. Many companies can supply proteins, but Deli Star can act as an industry resource as well.

“That’s our growth strategy, providing a forum for scientists, chefs and our customers to ideate and create value,” explains Justin Siegel, president of the company.

He and his brother Andrew, the director of supply chain, are the sons of company founder Dr. Dan Siegel Ph.D., who started the company 29 years ago. Dan Siegel, the chairman of the company, has a Ph.D. in meat science from the University of Illinois and is a packaging expert. He has been a consultant with Bemis for more than 30 years, and his latest venture, AMVAC Packaging, is poised to launch Deli Star into an entirely new direction.

The Siegel family has assembled an executive team that shares their desire to be something more than just a meat supplier.

“What I enjoy most is customers coming to us with a problem or a new possible project they are working on, and for us to be able to put our heads together and solve that problem,” explains Mike Weber, director of operations.

Deli Star’s latest evolution in customer service is the SLIC — the St. Louis Innovation Center. Located about an hour from the plant in Fayetteville in a historic neighborhood in St. Louis, the SLIC opened this year and features a state-of-the-art test kitchen and Executive Chef Jared Case. He recalls a recent ideation session with a customer that showcased all the company’s strengths.

“This sandwich maker wanted us to develop different flavors for chicken, so rather than show them three ideas that we had already, I set up the kitchen so that I could achieve pretty much any flavor profile that they could imagine,” he explains. “It took an investment from us, but rather than being a manufacturer in their eyes, we became a partner and a consultant. It really helped to bridge the gap between research and development, science, and the manufacturing process.”

Nitpicking and diversifying

Deli Star’s 60,000-square-foot facility has three lines, one to produce log products in a variety of proteins (turkey, chicken, ham and salami are just a few specialties). The second room is more versatile and can produce anything from deli logs to chicken salads. A third production area is a kettle room for salad dressings, barbecue sauce and other liquid products.

“Right now, we’re doing 350,000 pounds a week, and we have capacity to do 700,000 a week, depending on the product mix,” Justin says.

Deli Star’s customer base is divided into industrial, foodservice and a small amount of retail. The industrial segment, consisting of further processor customers, is about half of Deli Star’s business, and the remainder comes from national restaurant chains and QSRs. With a variety of packaging equipment on hand, Deli Star can supply everything from 1-pound retail packages to 25-pound pouches of barbecue sauce.

Many of Deli Star’s competitors are much larger, and the company does not compete on price alone. Dr. Siegel’s food science and consulting background has given him the chance to see hundreds of production environments, and he has used that knowledge to nitpick Deli Star’s processes, from the quality of the finished product to the efficiencies of its equipment. Food safety has become a key feature as well, and the company has invested in a post-pasteurization process that maximizes the shelf life of products.

One example of product innovation is the company’s rotisserie chicken log, which customers can use for chicken salad. Rather than dice its chicken and send the product to its customers, Justin notes that the company tried for years to convince its customers to invest in a dicer, which would give them cost savings in the long run.

“Finally we developed a rotisserie chicken breast log that breaks up in a ribbon blender or a paddle mixer, so they can throw it in, paddle mix or blend it, and add in the rest of the ingredients of the salad,” he says.

Since customers can break up the log with equipment they already own, Deli Star can sell the product below commodity cost. Furthermore, thanks to its pasteurization processes, Deli Star can ship the chicken refrigerated instead of frozen and still provide the shelf life that customers require. The end result is a never-frozen chicken log that can easily be broken up into chunks, resulting in a better taste and a better appearance.

“If they can buy into that partnership, they’re able to get that better product,” Justin says. “If they can just change their process, then they can reap the benefits of it.”

Deli Star uses its technical expertise on its processes as well as its products. Much of the equipment in its facility, down to the trolleys that carry meat into and out of the smokehouse, has been fine-tuned. One of the company’s most recent capital expenditures involved reconfiguring its chill cabinets.

“Over time, the performances of our chillers did not meet our standards. So instead of investing in pre-fabricated chill units, we designed and fabricated our own that are not only ultra-efficient, but also saved us money in the long run,” explains Dr. Siegel.

Deli Star also designed its own software program, Deli Server, to oversee all of the company’s in-plant processes. Andrew Siegel explains that the company has used its own software for more than a decade, but the original version wasn’t web-based.

“We decided to bring it to a third-party developer and make it web-based and a one-stop shop for as many aspects as possible,” he says. “Under the old system, we weren’t doing purchasing, production scheduling or raw inventory on it. On Deli Server, we do all those things, so it’s all very streamlined, with one location for everything.”

The software has proven to be so successful that there has been talk about commercializing Deli Server and selling it to other meat processors.

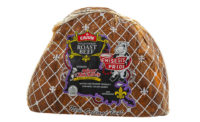

Deli Star’s product line continues to grow. Along with its line of deli products, it has a Gaucho Premium Slow-Cooked Meats brand of sous vide products, including slow-cooked pork. While it’s an ideal product for carnitas, Case is happy to demonstrate to customers how the pork can be used as a center-of-the-plate pasta dish as well. The Chef’s Edge brand is a premium line of deli meats, including turkey and rotisserie chicken, which was developed to respond to a need for a thicker, whole-muscle cut of meat.

Deli Star’s expertise in the deli meat category isn’t preventing it from looking into new ventures as well. The company is working on a line of cheeses designed to complement its deli meats, which will improve product quality for its sandwich maker customers.

“We study the cheese next to the turkey and the ingredients that prevent mositure migration and subsequently cold melt -- when the cheese looks melted on a cold sandwich,” Justin explains.

Another new development, AMVAC, will move the company into the fresh meats category for the first time. Dr. Siegel invented an award-winning packaging film, and he designed and built the packaging machine as well.

“My original goal with the AMVAC growth initiative was that we were going to design and build a skin packaging machine, and have the consumables that go with it, the trays and the film,” he explains.

He eventually decided to stay out of the equipment business and focus on the meat business. Deli Star will instead utilize the technology to partner with customers on skin-pack fresh meats. The initial concept will be to sell a line of burgers, including a beef-pork blend of sliders and “pub burgers.” The technology provides a shelf life that easily meets the USDA requirements of 34 days.

“We’re pushing the AMVAC line right now to be more patty focused, although we’ve shown that we can do the primals. If we were to get into the primal business, it would be as more of a partnership,” Justin says. “We would enable a small or medium-sized processor to do a New York Strip or a Ribeye.”

Along with those new initiatives, there is plenty more in the pipeline, including a sandwich-making seminar for its customers, guaranteeing that work at Deli Star won’t get boring.

Report Abusive Comment