|

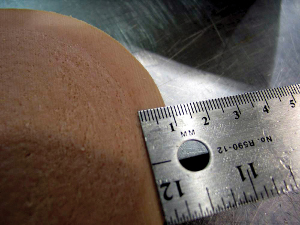

Linde helped West Liberty Foods find the ideal depth and temperature for crust-freezing deli logs to optimize high-speed slicing. |

West Liberty Foods LLC, (West Liberty, Iowa) is known for state-of-the-art hygienic practices throughout its high-speed meat-processing facilities. The Mount Pleasant, Iowa, plant packages a range of cooked protein products for major brands and deli retailers, which demand high-quality repeatability on stacked, fluffed and shingled slices.

To increase slicing productivity, plant manager Dave Greiwe reviewed upstream crust chilling operations with assistance from Linde North America (Murray Hill, N.J.). Griewe’s experience in meat and frozen food spans nearly 30 years — about half in quality control, so the investigation naturally centered on controlling variability.

“In order for us to be successful, cooling meat to the proper temperature is crucial. It became apparent we needed to establish a much tighter process at our facility so we could improve our overall effectiveness of slicing meat,” he says. Chilled beef, pork and poultry products arrive in Mount Pleasant from other West Liberty plants and suppliers, and are offloaded until ready for final processing. The slicing process uses clean room technologies to meet the highest standards in food safety.

Deli logs can benefit from crust freezing prior to slicing, especially at high speed.

“Firming up the protein enhances sliceability, quality and yield,” Griewe explains. “It just makes a better slice — and it typically impacts your throughput.”

Linde’s technical teamperformed an in-plant assessment and tested West Liberty’s roast beef logs at Linde’s Food Technical Center in Ohio to identify crusting parameters before installing the first Cryoline® MT tunnel freezer dedicated to crust freezing on a deli slicing line.

“The logs went from a storage temperature to an ideal slicing temperature, and Linde provided us with the rates, desired temperatures and physical characteristics of that log on the crust and the core,” Greiwe says. The modular tunnel freezer provided by Linde was primarily dedicated to the roast beef line.

The team ran other proteins to further explore the parameters between cryogenic crust freezing and slicing configurations. Ham, one of the plant’s high-volume products, represented a valuable opportunity. Once chilled, ham needs to be quickly sliced.

“We were slicing ham on several different lines, and we decided to put it all on one line with a high-speed slicer and a high-volume packaging machine,” he explains. The slicer can be fed with six full-size deli logs at once and cuts with a single blade that can travel at speeds up to 2000 rpm.

“We were using multiple methods of cooling, and that increased the potential for variation in core-to-crust temperature,” Griewe adds. To create greater slicing repeatability and minimize losses, Linde installed a new high-efficiency Cryoline MT hygeinic tunnel freezer in May 2011 for the ham line.

“We were using multiple methods of cooling, and that increased the potential for variation in core-to-crust temperature,” Griewe adds. To create greater slicing repeatability and minimize losses, Linde installed a new high-efficiency Cryoline MT hygeinic tunnel freezer in May 2011 for the ham line.

“We can now slice on that one line what it took two lines to slice,” Greiwe says.

Beyond the freezer’s capacity (over 10,000 lbs./hr.), West Liberty liked the smaller footprint and hygienic design, which provides full access to all internal surfaces for cleaning and sloped surfaces above and below the belt that drain unwanted moisture.

“It’s a fairly quick turnaround on sanitation.”

The new Cryoline MT tunnel line eliminates the variability associated with the mechanical and blast chillers, and gives the flexibility to recrust if there are short production delays. It also permits a more in-line process. Every protein has an ideal slicing temperature, and the cryogenic tunnel freezer helps control that key variable, Greiwe says.

“That’s the beauty of the Cryoline MT tunnel,” he says. “You identify that sweet spot, you put the log in the slicer, and you slice it. Those logs come in from the outside source, go right into the loading room, right into the tunnel, [and] are sanitized, peeled, loaded and sliced, all in minutes.”

Report Abusive Comment