Efficient deboning is paramount to optimizing production yield (maximizing the amount of meat removed from a chicken frame while reducing the presence of bones). For poultry processors, higher yield means higher profit, so every bit of meat removed counts.

Supporting ag innovation

|

Many processors evaluate the efficiency of their deboning lines through manual yield measurements, which involves using a special knife to scrape the chicken frame for any remaining meat after it has been deboned. The meat is then weighed to determine the potential meat loss.

This process, however, is not ideal for getting a consistent estimation of yield as the amount of meat measured can vary depending on the skill and fatigue level of the operator. In addition, scraping is time-consuming, limiting the number of frames that can be evaluated, potentially affecting the accuracy of the statistical predictions.

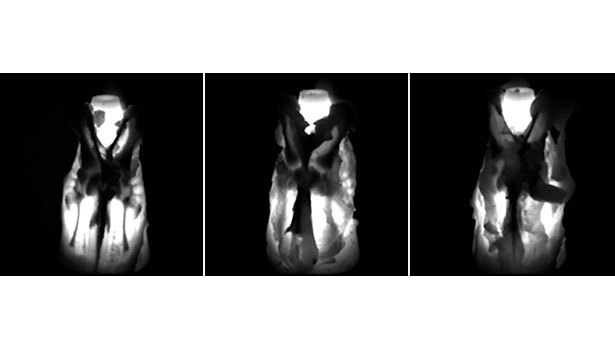

Researchers with the Georgia Tech Research Institute (GTRI) have developed an automated vision system for estimating yield loss by correlating image characteristics with the amount of meat left on a frame. Employing a special illuminated cone and sophisticated software algorithms, the Cone Line Screening System can make yield measurements in less than a second and has up to a 90 percent correlation with yield measurements performed manually.

As seen in Figure 1 (above), frames on the cone with more yield remaining inhibit light from transmitting, darkening those areas. This feature can be used to estimate yield loss.

“Yield management allows processors to monitor each deboning line’s performance in real time and set statistical process-control points to identify when any particular line is deviating from the expected performance,” says Colin Usher, research scientist and project director. As a result, he explains, processors can then immediately identify when a particular line is faltering and address the problem, potentially reducing yield loss.

The system can also characterize yield loss for individual regions on the frame such as the left and right clavicle and left and right tender areas. These characterizations, notes Usher, could allow processors to identify which workers on the line are fatigued or are exhibiting a drop in performance, adjust worker rotation schedules and placement of workers to better optimize the deboning line and determine when a particular worker is performing well enough to move from a training line onto a full-speed deboning line.

“Based on initial feedback from industrial partners, we believe the Cone Line Screening System could benefit processors by providing them with a better tool with which to control the deboning process,” says Usher.

The patented technology is now undergoing commercial testing as the YieldScan™ Rapid Yield Analyzer.

The benefits of monitoring yield loss on-line and in real time

Manual sampling of yield loss from several poultry processors has allowed researchers to determine that, on average, a standard broiler processing plant that processes small- to medium-size birds will lose anywhere from eight grams to 40 grams of meat per bird during the deboning process. Assuming a processor is operating in the median for yield loss, they would be losing an average of 20.1 grams of meat per frame. If they could adjust the process to shift yield loss into the lower 25 percent, they would instead lose an average 15.6 grams of meat per bird, or gain 4.5 grams per bird. The estimated impact of this shift in yield loss becomes:

- Assume 1 million birds per week

- Assume 4.5 grams savings per bird = 4.5 million grams (9,900 pounds) per week

- Assume $1.95 cost per pound* of breast meat = $19,305

- Assume 50 working weeks a year = $965,250 in additional revenue per year.

*Wtd. Avg. cents per pound of boneless/skinless breasts — Source: USDA Broiler Market News Report, February 14, 2014, Vol. 61, No. 20.

This article is an updated version of a previously published story from PoultryTech – to view the publication, visit www.atrp.gatech.edu.

Report Abusive Comment