Multi-Conveyor recently used similar side flexing Gripper Conveyor technology to produce two Ionizing Air Rinsers for two food applications. One unit is stainless steel with wash down components, and the other is of painted mild steel construction.

Two parallel Gripper designs were mounted with the gripper chains opposing each other on a support structure. This allowed the opening to be adjusted throughout the system by a single handwheel. An operator can easily adjust the compression for various container sizes using a simple digital readout.

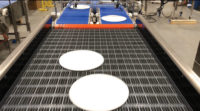

Each Gripper Rinser was a lowering design that received containers at elevations exceeding ten feet and delivered them down to the packaging line at just over three feet using an “S” configuration. 34” diameter disks used in each of the turns reduced tension on the chains to allow for line speeds up to 300 feet/minute or 600 parts/minute.

We partnered with Simco-Ion using their HS air nozzles provide powerful stream of ionized air to clean the containers and neutralize charges to prevent debris from re-attracting to the containers. Multi-Conveyor provided the manifold and vacuum system to contain and collect the debris through a cleanable filter system.

Energy saving, sustainable Paxton Ionizing Rinsers were used on the second gripper to tackle debris using a patented air nozzle manifold and high efficiency blower.

The Air Gripper Rinser also included pneumatic take-ups with pressure safety switches and air regulators to ensure proper tension on the gripper chains. Stainless steel roller base chain with rubber gripper bulbs was supplied on the wash down unit, while standard black roller base chain with jaw-type grippers was used on the mild steel unit, reducing cost. Each unit included stainless steel and lexan guards for the guarding of pinch points and moving components.

Side compression belts were used upstream of the Grippers to provide gapping of containers for rinsing and spacing during transport through the backflexing curve of the rinser. A timing screw was also provided on the second unit to provide gapping of product.

Gripper Rinsers can be provided in the S-Configuration lowering type as designed for these two applications; are also available in Upswing or Downswing designs that infeed and discharge products at the same elevation; or in C-style configurations that result in the product elevation changes with inverted orientation at discharge.

Gripper conveyors can also be provided without the rinser systems to simply move products from one elevation to another, or to invert product either within the gripper (to provide cap sterilization) or to discharge inverted product to another conveyor. NOTE: Air Rinsers are available in either a Compressed Air model or with a Motorized Blower.

For more information about Multi-Conveyor, or to get a quote on your next project, call toll-free 1-800-236-7960, e-mail info@multi-conveyor.com or visit www.multi-conveyor.com.

Report Abusive Comment