Watson-Marlow Fluid Technology Solutions is showcasing its high-efficiency pump technology for poultry processing and wastewater treatment applications at IPPE 2024, a global event for poultry, feed and meat technology. IPPE 2024 will be held at the Georgia World Congress Center in Atlanta from Jan. 30 to Feb. 1, 2024. WMFTS will be at Booth C27194.

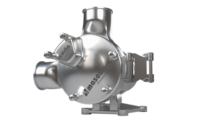

On display at the booth will be the MasoSine Certa Sine pump, designed specifically to offer high product quality through gentle handling and consistent flow rates of the pumped food material. With smooth, low shear flow rates of up to 1100 gallons per minute, Certa Sine pumps have shown success in marinated raw poultry applications, saving production time, reducing ingredient loss and improving line efficiency and product quality.

Also at the booth will be the Qdos range of chemical metering pumps, alongside the Bredel heavy-duty waste pumps. Together, they offer reliable and cost-effective performance in wastewater treatment operations in a wide range of industrial settings, including poultry meat processing.

The Qdos range of chemical metering pumps is designed to reduce operating costs without compromising on safety or accuracy. They offer accurate linear flow rates of up to 31.7 gallons per hour at variable fluid viscosity levels. The pumps come with multiple mounting options, skid, and POD systems for additional protection and reliability, even at high pressure. With abrasive handling capability, dry running and reversible features, Bredel hose pumps are suitable for handling most types of waste at poultry/other food processing facilities. These heavy-duty pumps are capable of suction lifts of up to 30 feet and waste flows of up to 475 gallons per minute.

Low cost of ownership is guaranteed across the entire WMFTS lineup of industrial pumps. The Certa Sine pump has low electricity consumption, reduced clean-in-place cycles and lower demand for cleaning agents. Both Qdos and Bredel pumps are designed to work without high-cost ancillaries like back pressure valves, seal-water flush systems or run-dry protection. All three pumps have long maintenance intervals that further drive down operating costs.

Source: Watson-Marlow Fluid Technology Solutions

Report Abusive Comment