Home » Keywords: » pathogen detection

Items Tagged with 'pathogen detection'

ARTICLES

Research collaboration aims to improve microbial detection tools.

Read More

Independent Thoughts

The National Provisioner Podcast Episode 154: DNA-based pathogen testing

May 25, 2023

Commentary | Regulations & Legislation

CSPI petitions FSIS to implement enforceable Salmonella controls, supply chain requirements

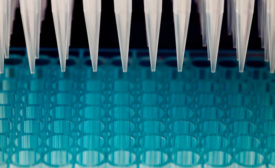

Read MoreFood Safety | Rapid Testing

Rapid testing enhances capabilities but must be accurate

Swift testing for microbials can enhance food safety and cut product waste, but obtaining the results in a timely manner can be daunting.

Read More

Food Safety

Rapid testing for pathogens in meat and poultry production

Need for (more) speed: Meat and poultry processors can generate greater yields while cutting protein waste by accelerating the testing for bacteria in production facilities.

Read More

Get our new eMagazine delivered to your inbox every month.

Stay in the know with The National Provisioner's comprehensive coverage of the meat and poultry processing industry.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing