The International Production & Processing Expo (IPPE) takes place January 25 to 27, 2022 at the Georgia World Congress Center in Atlanta, GA. As a provider of advanced automation solutions for the food industry, Stäubli Robotics is a must-see for inventively engineered robots used in food production, processing and packaging applications.

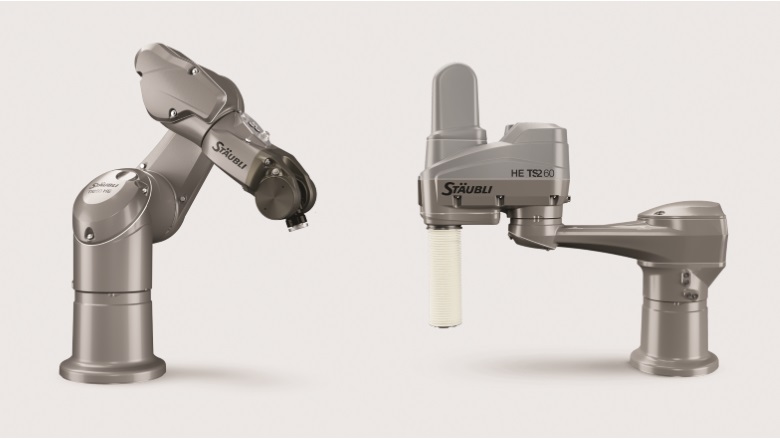

At Booth #C13663, food industry experts from Stäubli Robotics will demonstrate two production lines for processing and packaging meat, showcasing the capabilities of the Stäubli TS2-60 HE and larger TX2-90 HE six-axis robots.

The TS2-60 HE will carry out a chicken breast handling and thermoform loading operation, displaying high precision and speed: The robot picks the product up from a conveyor running at high speed and places it into its packaging. Product sterility is assured by the robot’s hygienic design, and integration is made easy by Stäubli’s VALtrack software.

The TX2-90 HE will run through several applications demonstrating its flexibility in handling different products and conducting wash-down procedures. After an initial self-cleaning at the first station, the robot moves to a chicken breast, picks up its cutting tool, and simulates waterjet cutting. Rotating to a third station, it picks up a meat patty, places it on a conveyor, and performs a meat washing application. After each cycle, the robot returns to the self-cleaning station.

Marty Albert, key account manager - Food Industry at Stäubli Robotics, will participate in IPPE’s TECHTalks with “Using Hygienic Environment (HE) Robotic Systems in Food Handling and Processing” on Jan. 26. The presentation will delve into the design solutions that enable robots to meet HACCP guidelines and other requirements, answering the question, “What makes a robot suitable for efficiently working and surviving in the harsh world of food handling and processing?”

In addition, several of Stäubli’s partners will demonstrate their own advanced food processing and packaging solutions incorporating Stäubli robots: JBT (Booth #C12743 / C12943), Sealed Air Corp. (Booth #C13225), and Ensight Solutions (Booth #C11231).

All of Stäubli’s HE robots are designed for use in wet/humid environments and full wash-down applications, featuring:

- Fully enclosed and pressurized structure to prevent microorganism penetration and avoid condensation

- Hygienic design with smooth, rounded and tilted surfaces to eliminate liquid retention

- Fully compatible with NSF H1 food-grade lubricant without loss of performance

- Protected against pressure jets of water (IP65) and immersion (IP67)

- Crucial components in stainless steel with special coating to withstand extreme conditions

- No external cables - all connections routed through the arm and base

- Unique, cylindrical envelope and small footprint

- Patented Stäubli proprietary JCS gearbox for top-of-the-line accuracy, repeatability and durability

Source: Stäubli

Report Abusive Comment