Food safety is a critically important task where the American consumer allows no margin for error. A single outbreak affects everyone’s livelihood, along with the brand equity and trust that takes years to build. Because of the potentially extreme consequences, the responsibility of reducing risk cannot be placed solely on the processing plants; it must be shared industry-wide.

Processing has traditionally been viewed as the last line of defense for safeguarding consumers from foodborne disease. But as an integrated company, your organization should make sure every person in the organization understands their role in helping the plant deliver the safest product possible.

Comprehensive Food Safety Begins at the Farm.

The biggest misconception by some in the poultry industry is that processing can solve all pathogen challenges. In order to ensure the best opportunity for in-plant interventions to work, we need to send the processing plant the lowest possible levels of Salmonella.

Pre-harvest intervention strategies, such as integrating Salmonella vaccines as part of a comprehensive food safety program, can help reduce the amount of Salmonella contamination brought to the processing plant. This allows the in-plant interventions to have a much greater chance of being effective, resulting in lower Salmonella contamination on finished products.

What Are Salmonella Vaccines?

Live Salmonella vaccines were introduced to the poultry industry over 20 years ago. Today, they are widely used in the egg-laying industry and in broiler breeders to help prevent Salmonella; however, their use in broilers is not as widespread. Why? There's a need to increase communication among processing decision-makers, influencers and live-side production to ensure all options are being fully considered.

Vaccination programs are typically determined by the teams that will ultimately implement the program —live-side production and company veterinarians. However, when it comes to food safety and controlling Salmonella, there is an opportunity to collaborate with a broader team.

Food safety, quality assurance and poultry processing professionals have an opportunity to influence the decision to use Salmonella vaccines as part of a comprehensive Salmonella control strategy, helping to reduce the amount of contamination brought to the processing plant and giving the in-plant interventions a much greater chance of being effective.

Salmonella Reduction Is a Shared Responsibility

Poultry processing plants do a tremendous job as the last line of defense, but too much Salmonella can stress the effectiveness of in-plant interventions. Live-side solutions, such as Salmonella vaccines, can help reduce Salmonella loads earlier in the process, so the entire burden doesn’t fall on in-plant interventions.

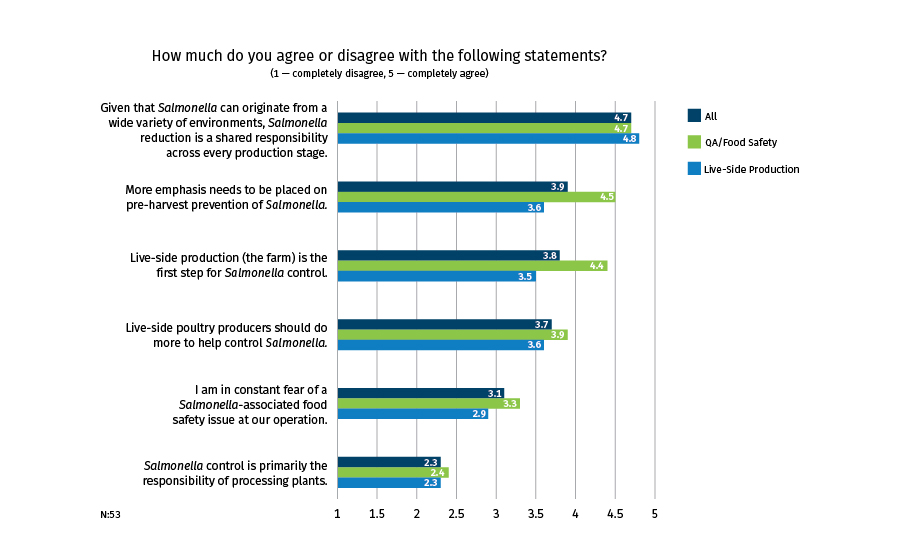

Elanco Food Safety fielded a blind industry survey with poultry quality assurance, food safety and live production professionals to outline the steps being taken to control Salmonella and identify who the poultry production chain believes is ultimately responsible for its control.

Live-side production: The first step in Salmonella control.

- Despite the generally acknowledged importance of controlling Salmonella, there remains some debate within the industry over whose ultimate responsibility it is. All respondents agree that Salmonella reduction is a shared responsibility across every production stage.

- Respondents with QA/food safety roles completely agree that live-side production is the first step to Salmonella control and more emphasis needs to be placed on the pre-harvest prevention of Salmonella.

- Those in live-side production roles don’t always see how they can play a part in food safety.

Live-side production wants to share the commitment to help control Salmonella. (Click the image for a larger version)

- Respondents agree that more dialogue is vitally important regarding how to control Salmonella throughout the poultry production chain.

- Those with QA/food safety roles feel more strongly about this statement than do their live-side production counterparts.

- 65% of live-side production respondents feel they should be sharing the commitment and investment in Salmonella control and feel they need to do more to help their QA/food safety counterparts control Salmonella.

(Click the image for a larger version)

What Can You Do to Help?

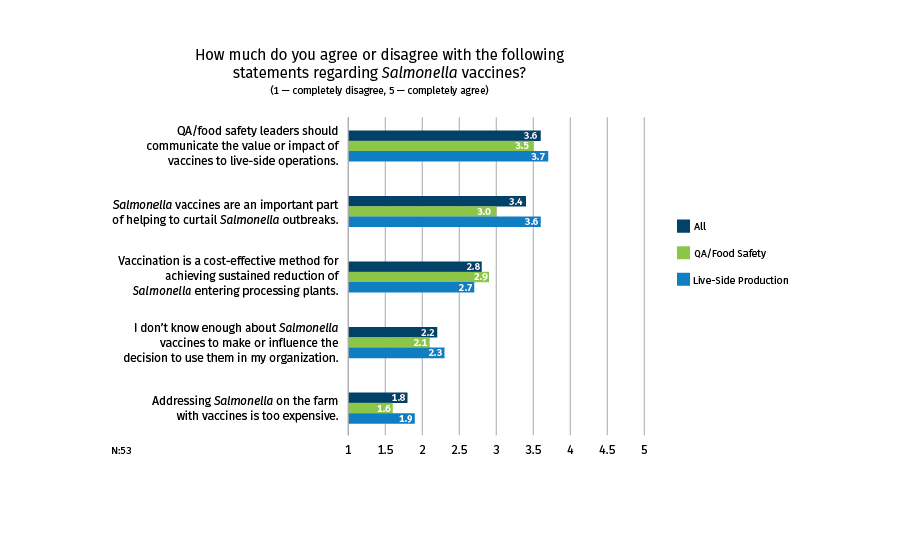

Based on the research, industry counterparts in live-side production — veterinarians and production managers — are looking to quality assurance and food safety professionals to help provide insights on effective Salmonella control interventions. This creates an opportunity for quality assurance and food safety teams to lead a conversation regarding how vaccines can help reduce the level of Salmonella contamination arriving at the processing facility.

Food safety can lead the conversation.

- Respondents agree that QA/food safety leaders should communicate the value or impact vaccines have on live-side operations.

- Those with live-side production roles feel more strongly about this than their QA/food safety counterparts.

(Click the image for a larger version)

How Do Salmonella Vaccines Work?

The major obstacle to Salmonella control in the poultry industry is the ubiquitous presence of Salmonella. Poultry can be latent carriers, shedding and spreading Salmonella, especially when stressed. Preventing colonization as early and effectively as possible reduces shedding and the subsequent spread of Salmonella.

Salmonella vaccines use tiny doses of live or killed (inactivated) bacteria to stimulate protective immunity in the chickens. Inactivated and live vaccines can be used in breeder birds (parent stock) and egg-laying hens, and live vaccines can also be used in meat birds (broilers and turkeys).

Live vaccines work by colonizing in the bird’s gut and competing with wild-type Salmonella strains, excluding those wild types from proliferating in the bird (“competitive exclusion”) while immunity is being developed.

In addition, vaccines can significantly lessen Salmonella in the crop and internal organs of poultry, which can further reduce the total load of Salmonella challenge facing broilers entering the processing facility.

The Proof Is in the Results.

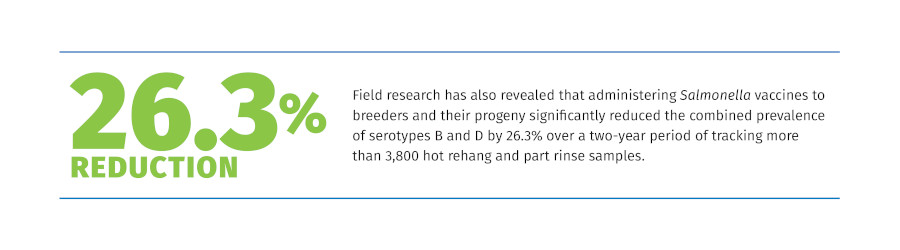

Salmonella vaccines have been proven to reduce the overall prevalence of Salmonella contamination of birds entering the processing facility, especially high-risk Salmonella B and D serotypes.

These serotypes include Enteritidis, Heidelberg and other highly zoonotic Salmonella serotypes that can be difficult strains to manage with in-plant interventions due to their presence in the meat, bone marrow and muscle of the bird. In addition, these serotypes have been some of the major causes of foodborne illness in humans.

(Click the image for a larger version)

Start the Conversation.

It takes the entire poultry industry working together to prevent a Salmonella outbreak and achieve FSIS Salmonella category 1 status. Food safety and quality assurance professionals can help lead the conversation, driving the adoption of live-side Salmonella interventions that help complement a plant’s industry-leading efforts.

Salmonella vaccines are proven to help take pressure off in-plant interventions, lowering Salmonella loads before the birds reach the processing facility. Plus, using Salmonella vaccines ensures that everyone in the production chain is sharing responsibility for Salmonella control.

Sometimes we must slow down to speed up. It is going to take a cooperative effort to pull in the right people at the right time to make sure we’re making the best decisions for the entire operation.

Elanco Food Safety has the resources to help start a discussion within your organization about reducing Salmonella loads in live birds. Elanco’s team of food safety experts and veterinary consultants are ready to help you lead the conversation.

To learn how Elanco Food Safety can help you start a comprehensive Salmonella control conversation, contact us. You can also visit Working Together for Food Safety and Salmonella 360 for more information.

Bill Potter, Ph.D.

Associate Advisor, Poultry Food Safety

Dr. Bill Potter received Ph.D. and MS degrees in Poultry Science from the University of Arkansas, and a BS in Animal Science with an MBA from Texas A&M. His areas of expertise include food safety, quality and pathogen intervention technologies.

Report Abusive Comment